Pane nguva dzaunoda kuchenesa bhodhi rako redunhu zvakakwana. Muchiitiko ichocho, ungada kubvisa solder yekare.

Asi kuti ubvise solder, iwe unozoda desoldering mudziyo kuti ushande nesimbi yekusimbisa. Ndeapi maturusi iwayo?

Zvino, kana iwe usingazive maturusi akasiyana ekuparadza, saka wauya kunzvimbo chaiyo! Kana iwe ukapfuura nechinyorwa ichi, iwe uchadzidza nezve akasiyana matekiniki uye maturusi aunga shandisa desolder.

Ipapo iwe unogona kusarudza kuti ndeipi nzira kana chishandiso chauchashandisa. Uye kana wapedza kusarudza, unogona kutanga kubvisa solder kubva kune zvakasiyana zvikamu uye mabhodhi.

Nekudaro, usati wadzidza nezvemhando dzakasiyana dze desoldering, unofanirwa kuziva kuti desoldering chii chaizvo. Saka ngatitangei!

Mune ino posvo isu tichafukidza:

- Chii chinonzi desoldering?

- Ndeapi maturusi anodiwa kuti desoldering?

- Nzira dzekubvisa solder

- 1. Braid nzira ye desoldering

- 2. Pombi nzira ye desoldering

- 3. Iron nzira ye desoldering

- 4. Kupisa pfuti desoldering nzira

- 5. Kupisa-mhepo rework station desoldering nzira

- 6. Compressed air desoldering nzira

- 7. Desoldering with tweezers

- 8. Desoldering nendiro inopisa

- 9. Desoldering girobhu nzira

- 10. Desoldering nemadrills

- 11. Desoldering neChip Quik

- Bvisa solder senge pro nemazano angu

Chii chinonzi desoldering?

Desoldering ndiyo nzira yekubvisa solder uye zvikamu zvakasungirirwa pabhodhi redunhu. Iyi nzira inonyanya kushandiswa kubvisa majoini e solder.

Kushandiswa kwekupisa kunodiwa pano.

Ndeapi maturusi anodiwa kuti desoldering?

Aya ndiwo maturusi auchazoda kubvisa iyo isingakoshi solder:

- Pombi inodonha

- Girobhu rinodzikira

- Inopisa soldering tweezers

- Kudzikisira kuruka kana tambo

- Kubvisa kuyerera

- Kubvisa alloys

- Pisai pfuti kana mweya unopisa

- Zviteshi zveRework kana chiteshi chekunamatira

- Vacuum uye kumanikidza pombi

- Zvisarudzo zvakasiyana-siyana uye tweezers

Nzira dzekubvisa solder

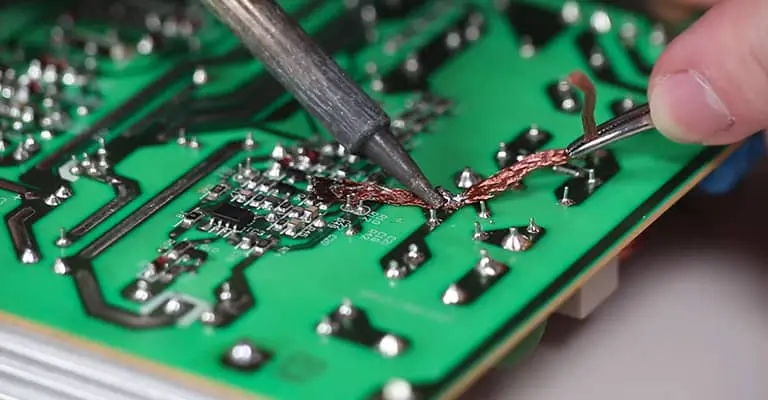

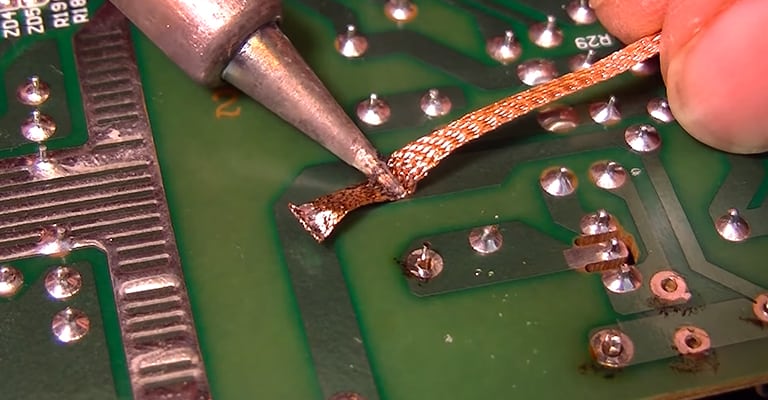

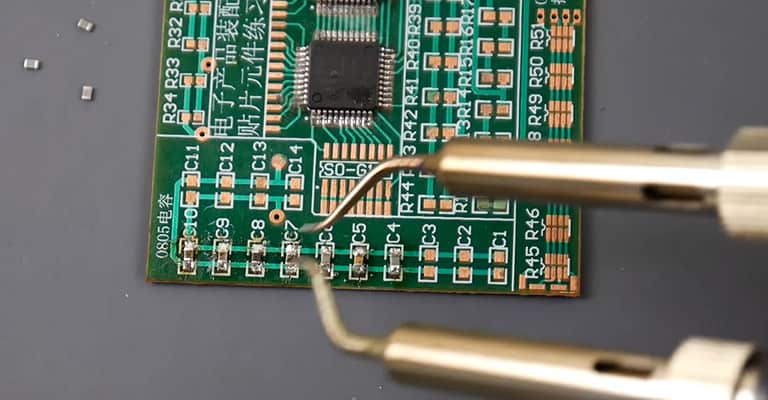

1. Braid nzira ye desoldering

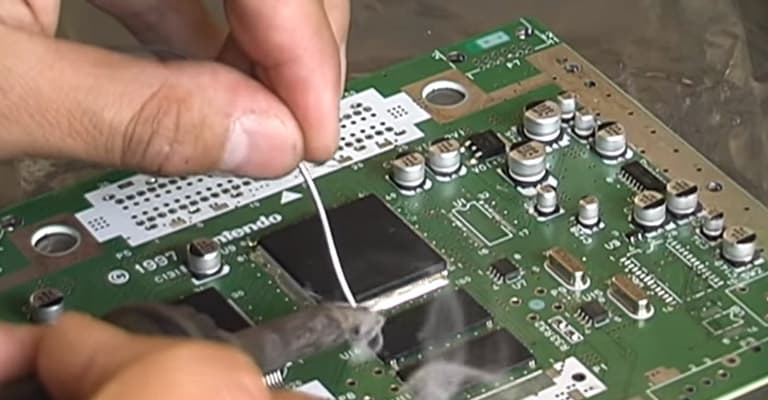

Mune iyi nzira, kana iwe uchipisa iyo solder, iyo yemhangura kuruka inoinyudza iyo kumusoro. Iwe unofanirwa kugara uchifunga kuti yemhando yepamusoro solder kuruka kwagara kune flux mariri. Zvakare, shenesa iron yesimbi pamberi pematanho aya.

Heano matanho:

Sarudza saizi ye braid

Kutanga, iwe unofanirwa kusarudza saizi ye desoldering braid nekuchenjera. Shandisa chirukwa chakaenzana nehupamhi kana kuti chakati faranuka pane chinotengeswa chauchange uchibvisa.

Shandisa iron yesimbi

Kuti ushandise chirukwa, gadzira gomba mune solder joint yaunoda kubvisa uye isa chirukwa pairi. Wobva wabata simbi inosungirira pairi kuitira kuti solder wick itore kupisa uye iendese kujoinhi.

Nguva dzose sarudza mhando yakasungirirwa yakarukwa

Zvino, mukuita uku, kuve nemhando solder braid kwakakosha. Kana zvisina kudaro, haizokwanisi kunyudza kupisa.

Nekudaro, kana iwe uine isina kusimba mhando solder, usaore moyo. Unogona kuzvigadzirisa nekuwedzera imwe flux.

Iwe unongo wedzera iyo kune chikamu chebraid yauchange uchishandisa. Uye unofanira kuzviita usati waisa pajoinhi.

Uyezve, kana iwe uchinzwa sekuti mubatanidzwa hauna solder yakakwana, unogona kuwedzera solder nyowani kujoini zvisati zvaitika.

Unozoona kuchinja kweruvara

Kana iyo solder yanyungudutswa, uchaona simbi yakanyungudutswa ichinyura murukwa ichichinja kuita tin ruvara.

Spool out more of the braid woenda kuchikamu chinotevera woenderera mberi nekuita kusvika joint yacho yanyatsonyura nekubviswa.

Bvisa iyo yesimbi simbi uye kuruka pamwe chete

Kana simbi yakanyungudutswa yangobviswa, simudza zvese simbi yesimbi uye sunga pamwe chete muchikwata chimwe. Paunobvisa simbi pamberi pebhandi, bhandi rakazara nesolder rinogona kutonhodza kubva nekukurumidza uye kusimbisa kudzoka kuchirongwa.

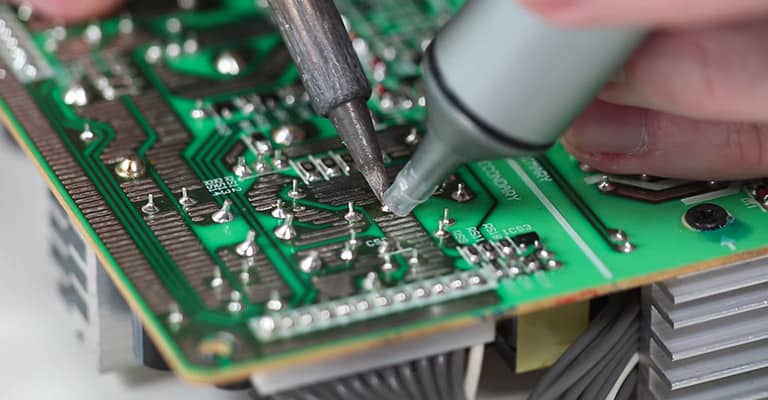

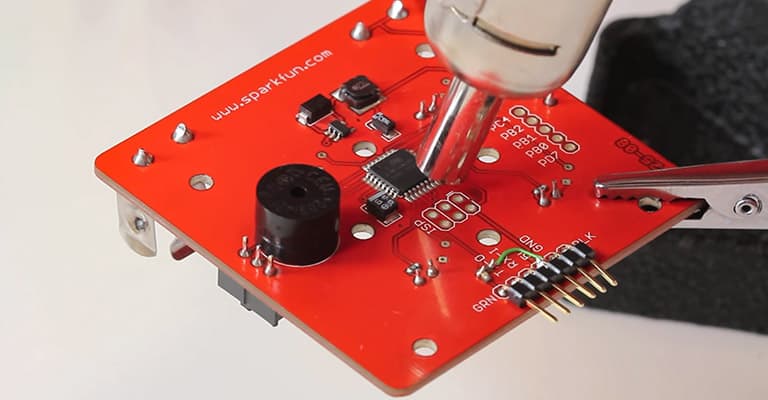

2. Pombi nzira ye desoldering

Pombi inoparadza (inozivikanwawo sekuti solder sucker kana solder vacuum) inoshandiswa kutsvaira zvidiki zvesolder yakanyungudutswa paunonyungudutsa majoini.

Rudzi rwemanyorerwo ndiyo inovimbika zvakanyanya yemudziyo uyu. Iine simba rekusveta rakavimbika uye rinogona kukurumidza kubvisa solder yakanyungudutswa.

Iyi ndiyo nzira inonyanya kufarirwa pakati nzira dzekubvisa solder isina iron yesimbi.

Gadzira chitubu

Kutanga, iwe unofanirwa kuseta chitubu chepombi ye solder.

Pisa iron soldering kune imwe tembiricha

Pisa iron soldering kwemaminitsi matatu.

Ita zvinyoro nyoro pakati pesimbi yekunyungudutsa uye iyo solder joint yaunoda kubvisa. Shandisa muromo wesimbi.

Ramba uchipisa solder kusvikira yanyunguduka.

Shandisa solder sucker

Zvino bata muromo wesolder sucker kune yakanyungudutswa solder uye solder pad. Edza kusashandisa chero kumanikidza.

Dhonza bhatani rekuburitsa

Mushure mekudzvanya bhatani rekuburitsa, piston inopfura kudzoka nekukurumidza. Izvi zvinogadzira kukurumidza kuyamwa kunodhonza solder yakanyungudutswa mupombi.

Kuchenesa pane yakanyungudutswa solder

Ipa solder yakanyungudutswa imwe nguva kuti itonhore uye wozodurura mudziyo wekusveta mumarara.

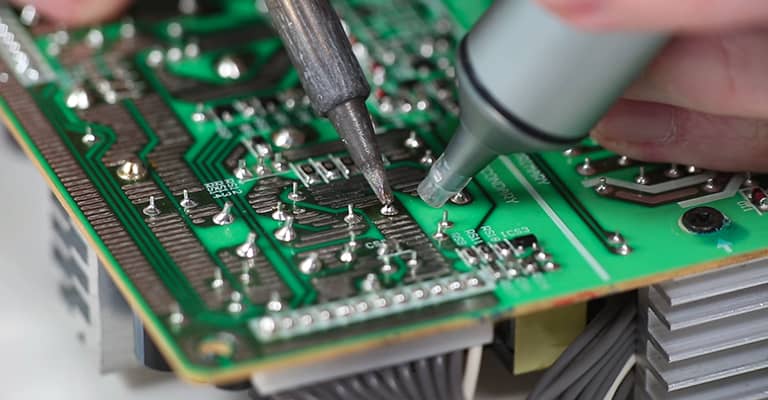

3. Iron nzira ye desoldering

Iyi nzira yakanyatsofanana nenzira dziri pamusoro.

Inoda chidimbu chesimbi inoparadza. Simbi inouya neyakavakwa-mukati yekusveta chikamu chinobvisa iyo solder yakanyungudika.

Isa muromo wesimbi inopisa kune imwe solder yaunoda kubvisa. Kana solder ichingonyunguduka, pombi inoyerera inobvisa solder yakanyunguduka.

4. Kupisa pfuti desoldering nzira

Kutanga, bvisa iyo PCB kubva kune iyo casings.

Iye zvino, iwe unofanirwa kupisa nzvimbo yacho nepfuti yako inopisa. Pano, iwe unofanirwa kuisa chinhu pane chimwe chinhu chisingabatike; nzvimbo yakapoteredza inofanirawo kunge isingabatiki.

Paunenge uchidziya, unoona solder ichipenya ichipenya; zvinoreva kuti iri kunyungudika. Zvadaro, unogona kubvisa solder uchishandisa tweezers kana maturusi akafanana.

Iwe unogona ikozvino kuiisa munzvimbo yakachengeteka kuti utonhorere.

5. Kupisa-mhepo rework station desoldering nzira

Iyo inopisa-mhepo rework station chishandiso chakanakisa chemabasa madiki aunoda kuita nekukurumidza. Icho chishandiso chinobatsira pakubvisa zvikamu zvekutengesa kubva kumabhodhi ekare edunhu.

Shandisa zvinotevera matanho:

Sarudza muromo wako

Iwo madiki akanakira kushanda pazvinhu zvidiki, nepo iwo makuru ari makuru kune akakosha nzvimbo dzebhodhi.

Chinja pane chishandiso

Ukangobatidza mudziyo, unobva watanga kudziyisa. Gara uchidziya chiteshi chemhepo inopisa usati waishandisa.

Vangisa muromo; unogona kuona tuhutsi tuchena huchibuda mairi. Zvakanaka, izvi zvakajairika, saka haufanirwe kunetseka nazvo!

Chinja mweya uye tembiricha

Kune maviri akasiyana mapfundo kune rimwe nerimwe. Isai mafambiro emhepo uye tembiricha yakakwira kupfuura nzvimbo yekunyungudika yesolder.

Nyorera kuyerera

Nyorera flux kune yakabatana solder iwe yaunoda kubvisa.

Chinangwa kamwene

Zvino zvawagadzirira, yave nguva yekunongedza muromo pane chikamu chauchange uchishanda pachiri. Ramba uchifambisa muromo uchienda mberi uye mberi kusvikira solder yatanga kunyunguduka.

Iye zvino nyatso bvisa chikamu icho chaunoda kuti ushande zvakare nema tweezers. Ngwarira mhepo inopisa.

Rega mudziyo utonhore

Dzima mudziyo kuti utonhore. Geza bhodhi kuitira kuti pasara mvura inonyungudika. Kana zvikasara, izvi zvinogona kukonzera ngura.

6. Compressed air desoldering nzira

Nokuda kweiyi nzira, iwe unongoda chete simbi yakanyungudutswa uye mhepo yakamanikidzwa. Unofanira kupfeka magirazi ekuchengetedza. Iyi tekinoroji yakashata zvishoma, asi yakatwasuka.

Pakutanga, iwe unofanirwa kupisa simbi yekusimbisa. Bata zvinyoro nyoro mubatanidzwa we solder waunoda kubvisa.

Wobva wapisa mubatanidzwa we solder uye shandisa mweya wakadzvanywa kuti ufuridze solder. Uye maitiro aitwa!

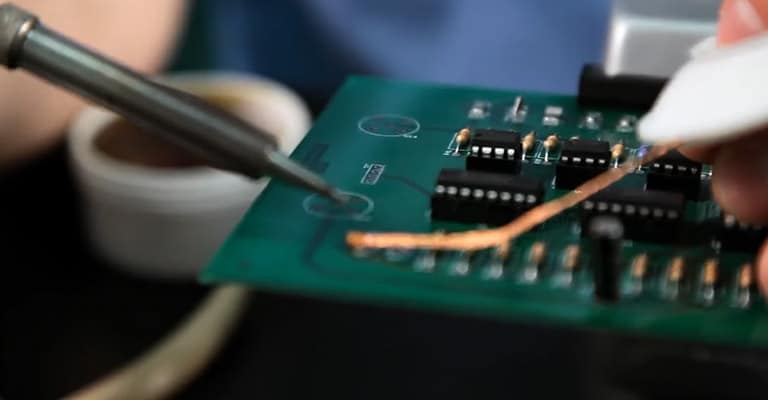

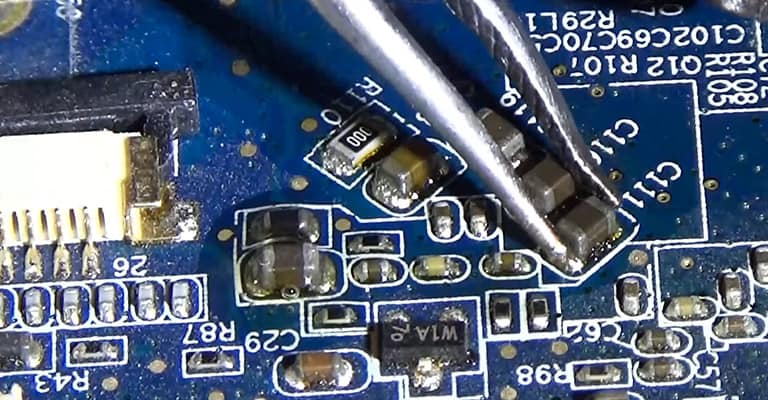

7. Desoldering with tweezers

Vanhu vanonyanya kushandisa desoldering tweezers kunyungudutsa solder panzvimbo chaiyo. Iwo ma tweezers anouya ari maviri mafomu: angave anodzorwa ne chiteshi chekutengesa kana kusununguka kumira.

Kunyanya, iwo 2 matipi echishandiso anoshandiswa mu desoldering; iwe unofanirwa kushandisa mazano kune 2 terminals yechikamu.

Saka ndeipi nzira yekubvisa? Ngatipfuure neizvozvo!

Dzorera izvo

Kutanga, iwe unofanirwa kushandura ma tweezers uye kuseta tembiricha. Unogona kutarisa bhuku racho kuti uwane mirairo yakazara.

Kugadzira kubatana kwakanaka pakati pema tweezers uye chikamu, unogona kushandisa flux kana kuwedzera solder.

Sungunusa solder kure

Kune izvi, isa muromo wetweezers pane iyo nharaunda uye mirira kusvikira iyo solder yanyungudika.

Bata chikamu uchishandisa tweezers

Iye zvino kuti solder yakanyungudutswa, tora chikamu nekusvina zvinyoro nyoro. Simudza chikamu uye uende nacho kunzvimbo itsva kuti usunungure ma tweezers.

Unogona kushandisa chishandiso ichi kune zvikamu zvine 2 terminals, senge resistors, diode, kana capacitor. Iyo yekuwedzera poindi yekushandisa ma tweezers haapise zvimwe (zvakatenderedza) zvikamu.

8. Desoldering nendiro inopisa

Vanhu vanowanzo shandisa magetsi ndiro inopisa kupisa bhodhi kune kupisa kwekushisa, pamwe nekubvisa mabhiriji ekutengesa kubva pabhodhi.

Iwe unozoda chidimbu chesimbi chakatsetseka, simbi yekunyungudutsa, uye tambo yekusimbisa. Iyo simbi ndeyekuisa bhodhi yako pane inopisa ndiro.

Ngationei maitiro.

Wedzera solder paste kubhodhi rako

Iwe unofanirwa kuwedzera solder paste kubhodhi rako. Iwe unogona kushandisa sirinji kuisa zvakananga solder kune mapedhi aunoda. Zvakachipa futi!

Ita shuwa yekuisa solder paste pakati peseti yepini. Iwe haufanirwe kunetseka nezve kuisa yakawandisa pairi nekuti unogona kubvisa zviri nyore zvimwe gare gare.

Isa chip kune solder paste

Iye zvino iwe unofanirwa kuisa chip kune solder paste uye tarisa kana yakaiswa nemazvo.

Shandisa chidimbu chesimbi

Shandisa chidimbu chesimbi kuisa bhodhi pairi. Zvadaro woiisa pane inopisa ndiro uye shandura chigadzirwa chacho.

Sarudza iyo chaiyo tembiricha yeichi chiitiko

Iwe haudi kuti bhodhi rako ripise zvekuti rinotanga kukuvadza machipisi uye epoxy inosunga bhodhi redunhu. Iwe unofanirwa kuita kuti zvidziye zvakakwana kuita kuti solder ienderere.

Muchiitiko ichi, iwe unofanirwa kuve neruzivo rwekugona kwehot plate yako zvisati zvaitika. Zvadaro, isa dial kune tembiricha yakakodzera uye mirira.

Pashure penguva yakati, solder inotanga kunyunguduka. Uchaona solder ichishanduka kupenya.

Iwe unozoona mamwe mabhiriji ekutengesa

Yakazara yakanyungudutswa solder mashizha solder mabhiriji. Kana solder yapedza kufamba, dzima mudziyo, bvisa simbi ine bhodhi, uye ita kuti itonhorere pasi.

Shandisa desoldering braid uye iron

Iye zvino unogona kushandisa desoldering braid uye iron kubvisa mabhiriji ekutengesa. Iwe unogona kutevera maitiro e desoldering braids ambotaurwa.

9. Desoldering girobhu nzira

Nekuita uku, iwe uchada girobhu rekubvisa uye simbi yekunyungudutsa. Bhabhu rinoparadza rinoshandisa vacuum chiito kubvisa solder nekukurumidza uye nyore.

Unoshandisa sei girobhu rinodzikira?

Pisa simbi inotengeswa uye uishandise kunyungudutsa solder yaunoda kubvisa.

Dzvinyirira girobhu neruoko rumwe wobata solder yakanyungudika nemuromo wegirobhu. Isunungure kuitira kuti solder isvikwe mugirobhu.

Mirira kusvikira solder ichitonhora pasi. Zvadaro, unogona kubvisa muromo uye kusunungura zviri mukati megirobhu.

Kunyangwe chishandiso ichi chisina simba rakawanda rekukweva, hausi panjodzi chero kukuvara kubva pachiri. Iwe unogona kushandisa nzira iyi kana iwe uchida kubvisa chaiyo chiyero che solder.

10. Desoldering nemadrills

Iwe unogona kushandisa chibooreso cheruoko chidiki mukuita uku. Zvakare, unogona kushandisa pini vise ine diki dhiri. Tenga madrills zvichienderana nehukuru hwegomba raunoda kusunungura.

Vanhu vazhinji vanofarira kushandisa zvibooreso mushure mekushandisa girobhu rekubvisa. Mushure mekunge wasveta solder negirobhu, unogona kuburitsa solder yasara kana iripo.

Iwe unofanirwa kushandisa iyo cobalt, kabhoni, kana yakakwirira-kumhanya simbi drill bits, asi usamboshandisa carbide imwe. Uye chenjera paunenge uchishanda nechibooreso chakakura.

11. Desoldering neChip Quik

Iyo Chip Quik yekubvisa alloy inodzikisa tembiricha yesolder nekuisanganisa neiyo iripo solder. Izvi zvinobatsira kukurumidzira dhizaini uye kuchengetedza solder yakanyungudutswa kwenguva yakareba.

Kana iwe uchifunga kubvisa akakosha epamusoro ekuisa senge maIC, unogona kushandisa Chip Quik. Iwe unogona kubvisa zvikamu zveSMD nesimbi yekusimbisa pane kushandisa mhepo inopisa rework station.

Bvisa solder senge pro nemazano angu

Paunenge uchinge wajaira nzira ye desoldering, richava basa rinonakidza kuita!

Zvisinei, kune dzimwe nzira dzakawanda dzekubvisa solder. Semuenzaniso, kana iwe uchida kubvisa solder kubva kumabhodhi edunhu, unogona kutevera nzira yekutanga desoldering, iyo iri kugaya nekukwesha.

Kugadzira solder ndeimwe nzira, kunyange ichida ruzivo rwakanyanya uye unyanzvi.

Kana iwe uchida kubvisa solder kubva pamahwendefa emhangura, unogona kuita kemikari kubvisa. Uyezve, dzimwe nguva, ungangoda kuputika PCB yako uchibvisa solder kubva panzvimbo hombe.

Zviripachena, iwe unofanirwa kusarudza pane nzira nekungwarira; Kunzwisisa nzira dziri pamusoro apa kuchabatsira zvikuru, sezvo iwe uchizoziva kuti ndeipi nzira yakanyatsokodzera basa rako.

Nzira dzataurwa muchinyorwa chino dzinopa yakanakisa kutanga kudzidza kuita desolder.

Ini ndini Joost Nusselder, muvambi weZvishandiso Chiremba, mushambadzi wemukati, uye baba. Ini ndinoda kuyedza michina mitsva, uye pamwe nechikwata changu ndanga ndichigadzira zvakadzama blog zvinyorwa kubva 2016 kubatsira vaverengi vakavimbika nematurusi & matipi ekugadzira.