Ini ndinoda kugadzira yemahara zvemukati izere nemazano evaverengi vangu, iwe. Ini handigamuchire yakabhadharwa mari, maonero angu ndeangu, asi kana iwe ukaona zvandinokurudzira zvichibatsira uye ukazopedzisira watenga chimwe chinhu chaunofarira kuburikidza nehumwe hukama hwangu, ndinogona kuwana komisheni pasina imwezve mari kwauri. Dzidza zvimwe

Iyo nharo yemakore, handifungi kuti iyi post ichave kuguma kwayo. Asi ndine chokwadi chekuti unogona kuve nechokwadi chezvinodiwa kana zvasvika pakusarudza pakati pezviviri. Hongu, vaviri vacho vanotaridzika zvakafanana, asi vakangofanana.

Mune ino posvo isu tichafukidza:

Ko Soldering Inogona Kutsiva Welding?

Ehe, iwe unogona kuita soldering panzvimbo yewelding dzimwe nguva. Kunze kwezvo, soldering ndiyo yega sarudzo yemakesi ayo maviri masimbi haagone kusungirirwa. Soldering uye welding, maitiro maviri aya akafanana, asi maitiro avo uye sub-tekiniki akasiyana. Zvisinei, majoini akasungwa anonzi akasimba. Zvinhu zvisina-ferrous semhangura nendarira zviri nani kutengeswa pane weld. Kune zvimwe zviitiko, kana zvakaumbwa, zvinokurudzirwa kuti weld pane solder. Kana isiri-yakarongeka, unogona solder pane welding. Asi mubatanidzwa wacho unogona kunge usina kufanana.Welding vs Soldering

Kufanana neakawanda ematemu esimbi simbi, soldering uye welding zvinoshandiswa zvinoenderana. Ose mazwi maviri aya anotorwa senzira dzekubatanidza simbi. Asi zviyero uye maitiro akasiyana. Nekuziva nezve aya maviri mazwi nemazvo, iwe unowana pfungwa yakajeka yekuti ndeipi nzira yakanakira zvaunoda.

Mhando dzeWelding

Welding inguva-yakaedzwa kuveza maitiro ezvigadzirwa, kunyanya simbi uko kupisa kwakanyanya kunoshandiswa kunyungudutsa base simbi uye fuse zvikamu. Iyo nzira inoshandiswa kugadzira kubatana pakati pesimbi mbiri. Asi panzvimbo yekushisa, high pressure inogonawo kushandiswa. Kune mhando dzakasiyana dzewelding. Rondedzero iri pasi apa. MIG Welding MIG welding inozivikanwawo seGas Metal Arc welding. Imhando yakakurumbira uye yakapusa uye inokurudzirwa zvakanyanya kune vanotanga. Welding iyi inosanganisira marudzi maviri. Mhando yekutanga inoshandisa yakavhurika kana tambo waya uye iyo inotevera inoshandiswa iyo flux core. Bare wire welding inoshandiswa kubatanidza simbi dzakatetepa dzakasiyana. Kune rimwe divi, MIG flux core welding inoshandiswa kushandiswa kunze sezvo isingade chero yekuyerera mita uye gasi kupihwa. Kana iwe uri hobby welder kana DIY anofarira, iyi welding process yakanakira kuenda. Kana zvakadaro, cherechedza kuti pane specialized pliers yeMIG welding. TIG Welding TIG welding inozivikanwa seGasi Tungsten Arc welding. Ndiyo inonyanya kufarirwa uye yakasiyana-siyana mhando yewelding. Asi welding iyi ndeye nhanho yehunyanzvi uye inonetsa kunyorera. Iwe unofanirwa kushandisa maoko ako ese nehunyanzvi kuita yakanaka TIG welding. Rimwe remaoko ako rinoda kudyisa tsvimbo kana simbi yaunoda kupinza nepo rumwe ruoko ruchida kubata a TIG torch. Torch inogadzira kupisa uye arch kuti iwedzere simbi dzakawanda dzechinyakare dzinosanganisira aluminium, simbi, nickel alloys, mhangura, cobalt, uye titanium. Stick Welding Tsvimbo welding inoonekwa seShielded Metal Arc Welding. Murudzi urwu rwekuita, welding inoitwa nenzira yechinyakare. Zviri nyore pane TIG welding asi yakaoma pane MIG welding. Kuti ugadzire tsvimbo, iwe unoda tsvimbo ye electrode welding. Plasma Arc Welding Plasma Arc welding inyanzvi uye yemazuva ano tekinoroji inoshandiswa zvakanyanya mukushandiswa kweaerospace uko ukobvu hwesimbi hunosvika 0.015 inches senge blade yeinjini kana chisimbiso chemhepo. Maitirwo eiyi welding akafanana zvakanyanya neTIG welding. Kutengesa Gesi Gasi Welding hainyanyi kushandiswa mazuva ano. TIG welding yakatora nzvimbo yayo zvakanyanya. Kune rudzi urwu rwekupisa, okisijeni uye acetylene zvinoshandiswa uye zvinotakurika zvakanyanya. Inoshandiswa kugadzira mabheti emagetsi emagetsi kumashure pamwe chete. Electron Beam uye Laser Welding Imhando yewelding inodhura zvikuru. Asi mhedzisiro yewelding iyi inouyawo nemazvo. Iyo mhando inoonekwa seyakanyanya simba welding nzira.Mhando dzeSoldering

Solder inzira yekubatanidza simbi mbiri kana kupfuura pamwechete pasina kunyungudutsa simbi yepasi. Basa rinoitwa nekuisa alloy yakasiyana inonzi solder pakati pesimbi mbiri uye iyo solder inonyungudutswa kuti ibatanidze. Kune marudzi akasiyana ekutengesa akadai sesoldering yakapfava, hard soldering, uye brazing. Hard Soldering Iyo yakaoma solder process yakaoma kupfuura iyo yakapfava. Asi chisungo chinogadzirwa nenzira iyi chakasimba zvikuru. Kupisa kwepamusoro kunoshandiswa kunyungudutsa solder yeiyi soldering. Kazhinji solder inoshandiswa mukuita uku indarira kana sirivheri uye kuinyungudutsa blowtorch inodiwa. Kunyangwe kunyunguduka kwesirivheri kwakadzikira pane ndarira, inodhura. Hard soldering inozivikanwawo sesirivha soldering kana inoshandiswa nesirivha. Kubatanidza simbi dzakaita semhangura, ndarira, kana sirivheri, sirivheri solder inoshandiswa. Brazing Brazing inoonekwawo semhando ye solder. Inosanganisira solder material ine yakanyanya kunyungudika pane iyo inoshandiswa mukuoma uye munyoro solder. Asi kana tichienzanisa, yakanyanya kufanana neyakaoma soldering. Masimbi epasi anopisa uye panguva iyoyo inopisa, solder inonzi brazing filler material inoiswa pakati. Iyo solder inonyungudutswa pakarepo mushure mekuiisa. Nekudaro, pane misiyano pakati peyakajairwa soldering uye brazing.Zvinhu Zvaunofanira Kufunga

Soldering inowanzoda tembiricha yakaderera sezvo simbi yepasi haina kunyungudutswa uye nekudaro nzvimbo yekunyunguduka yesolder inofanirwa kunge yakaderera pane base simbi. Asi ivo bond yakagadzirwa ne soldering haina kusimba sewelding senge muwelding hapana imwe simbi inoshandiswa pakati. Nheyo dzesimbi dzakanyungudutswa uye dzakabatanidzwa pamwe chete izvo zvinovimbika zvakanyanya. Welding zviri nani kune simbi dzine nzvimbo dzakakwirira dzekunyungudika. Kujoinha simbi dzakakora, welding ndiyo yakanakisa. Kana iwe uchida kusanganisa zvizere zvidimbu zviviri zvesimbi munzira yese kwete pane imwe nguva, welding haizove sarudzo yakanaka. Kune simbi dzakatetepa uye kana iwe uchida kupera isina musono, soldering ichava nani.

Chii chinonzi Soft Soldering?

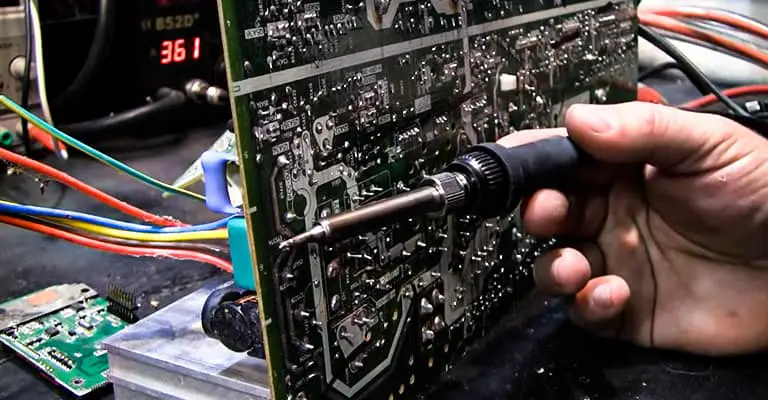

Iyo yakapfava solder process yakakurumbira mumagetsi uye maindasitiri epombi. Iyi nzira inoshandiswa kugadzira chisungo pakati pezvikamu zvemagetsi padunhu. Mukuita uku, solder inogadzirwa netin, lead, uye mamwe marudzi esimbi. Kuti uve nechokwadi chekuenderana kwakasimba, iwe inogona kushandisa chinhu chine acid chinonzi flux. Mukunyorovesa solder, ingave yemagetsi kana gasi-powered solder iron inoshandiswa. Chisungo chakagadzirwa neichi soldering chakanyanya kusimba pane chakaoma solder. Asi nekuda kwekureruka kwayo, solder iyi inowanikwa kune vanotanga.Ko Soldering Kwakanaka SekuWelding?

Sezvambotaurwa, soldering haina kusimba sewelding. asi kune dzimwe simbi, soldering inoshanda zvakanaka sewelding. Kunyangwe kune mamwe masimbi, semhangura, ndarira, sirivha soldering inoshanda zvirinani pane welding. Pamidziyo yemagetsi, pombi dzemvura uye zvishongo, soldering inoita kukurumidza uye kwakatsvinda kubatana.Yakasimba Zvakadii Solder Joint?

Iyo yakatengeswa 4-inch mhando L-joint inowanzouya nekudzvanywa rating ye440 psi. sirivheri solder ye tembiricha yakaderera ine tensile simba rinenge 10,000 psi. Asi vatengesi vesirivheri vanogona kuve nekusimba kwesimba pamusoro pe60,000 psi iyo yakaoma kwazvo kuwana.Ko solder Joints Fail?

Hongu, iyo solder joint inoderedza nekufamba kwenguva uye inogona kukundikana. Kunyanya kuremedza, zvichikonzera kutyora kwekunetseka, kunogara kwenguva refu kurodha uye cyclic kurodha kunoita kuti soldering itadze. Iko kukundikana kunowanzozivikanwa se creep uye kunokonzerwa nekupisa kwakanyanya. Asi nekuda kwezvikonzero zviri pamusoro, zvinogonawo kuitika pane tembiricha yekamuri.Ko Brazing Yakasimba kupfuura Welding?

Majoini akakodzera anogona kusimba kupfuura masimbi ari majoini. Asi havagone kusimba kupfuura majoini akasungwa. Kune welding base zvinhu zvakabatanidzwa uye zvigadziko zvine simba kupfuura zvinhu zvekuzadza. Filler zvinhu zvine yakaderera kunyungudika. Saka tembiricha inodiwa yakadzikira, asi musimba, hadzina kufanana.Welding Vs Brazing

Welding inojoinha simbi nekusanganisa simbi dzepasi nepo, brazing inojoinha simbi nekunyungudutsa zvinhu zvekuzadza. Iyo filler material inoshandiswa yakasimba, asi tembiricha inodiwa pakubhuroka yakadzikira pane yewelding. Saka, brazing inopedza simba shoma pane welding. Asi kune dzimwe simbi dzakatetepa, brazing inogona kuve iri nani sarudzo.Brazing Vs Soldering

Musiyano uripo pakati pavo kupisa. Kazhinji, mukutengesa, iyo yekuzadza zvinhu ine nzvimbo yekunyungudika pazasi 450C. Asi pakugadzira, zvinhu zvinoshandiswa zvine nzvimbo yekunyunguduka pamusoro pe450C. Brazing ine simba shoma pane simbi pane soldering. Kubatana kunoitwa nesolder haina kusimba kupfuura iyo yebrazing.FAQ

Q: Ndeipi simbi isingagone kutengeswa? Mhinduro: Kazhinji, simbi dzese dzinogona kutengeswa. Asi mamwe akanyanya kuoma kugadzira solder, saka zvakanaka kuti usazvitengesa sesimbi isina tsvina, aruminiyamu, bhuronzi, nezvimwe. soldering aluminium uchishandisa soldering iron zvinoda kutarisirwa chaiko. Q: . Pane guruu rinoshanda semusoja here? Mhinduro: Ehe, MesoGlue isimbi glue inogona kushandiswa panzvimbo ye solder. Ichi chigadzirwa chinoshanda pakamuri tembiricha uye simbi glue inokwanisa kunamatira zvidimbu zvesimbi pamwe nekukasira spontaneity nemagetsi kutonga. Q: Ndinoda here kushandisa flux kune solder? Mhinduro: Hongu iwe zvinoda kushandisa flux kana isina kuwedzerwa kune solder. Kazhinji, mazhinji emasoja anoshandiswa pakushandiswa kwemagetsi ane mukati memukati wekuyerera, kana zvakadaro, haudi imwe.mhedziso

Kuve mushandi wesimbi kana hobbyist, unofanirwa kuziva nezve welding uye soldering. Kana ukazvitora sezvisina basa, unogona kusambowana mhedzisiro yawakatarisira. Kunyangwe dzakafanana kubva kunze, zvimwe zvinhu zvikuru zvakavaita nzira mbiri dzekutanga dzekubatanidza simbi. Ichi chinyorwa chakanangana neruzivo rwechokwadi rwekushongedza, soldering, uye brazing zvakare. Ndinovimba, ichabvisa kuvhiringidzika kwese pamatemu, misiyano yavo, kufanana, uye minda yekushanda.Ini ndini Joost Nusselder, muvambi weZvishandiso Chiremba, mushambadzi wemukati, uye baba. Ini ndinoda kuyedza michina mitsva, uye pamwe nechikwata changu ndanga ndichigadzira zvakadzama blog zvinyorwa kubva 2016 kubatsira vaverengi vakavimbika nematurusi & matipi ekugadzira.