Ndiyakuthanda ukudala umxholo okhululekileyo ogcwele iingcebiso kubafundi bam, wena. Andilwamkeli uxhaso oluhlawulelweyo, uluvo lwam lolwam, kodwa ukuba ufumanisa ukuba izindululo zam ziluncedo kwaye ugqibela ngokuthenga into oyithandayo ngenye yeekhonkco zam, ndingafumana ikhomishini ngaphandle kwendleko ezongezelelweyo kuwe. Funda nzulu

Impikiswano endala, andicingi ukuba esi sithuba siyakuba sisiphelo sayo. Kodwa ndiqinisekile ukuba ungaqiniseka ngento efunekayo xa isiza kuthatha isigqibo phakathi kwezi zimbini. Ewe, ezimbini zazo zikhangeleka zifana, kodwa azifani.

Kule posi siza kugubungela:

- Ngaba ukuSoldering kuyibuyisela iwelding?

- Ukuwelda ngokuSoldering

- Yintoni iSoldering Soldering?

- Ngaba ukuSoldering kulunge njengeWelding?

- Yomelele kangakanani indibaniselwano yeSolder?

- Ngaba amaLungu eServer ahluleka?

- Ngaba iBrazing yomelele kuneWelding?

- Ukudibanisa iVs Brazing

- Ukuqhawula nge-Brazing Vs

- FAQ

- isiphelo

Ngaba ukuSoldering kuyibuyisela iwelding?

Ewe ungenza ukurhafisa endaweni ye-welding ngamanye amaxesha. Ngaphandle koko, i-soldering kuphela kwendlela apho iimeko apho izinyithi zombini zingenakudityaniswa khona. I-Soldering kunye ne-welding, le misebenzi mibini iyafana, kodwa inkqubo kunye neendlela ezingafaniyo zahlukile. Nangona kunjalo, amalungu adibeneyo athathwa njengamandla. Izinto ezingekho-ferrous ezifana nobhedu kunye nobhedu zibhetele kwi-solder kune-weld. Ngamanye amaxesha, ukuba ulwakhiwo, kucetyiswa ukuba kudityaniswe endaweni yokuthengisa. Ukuba ayilolwakhiwo, unokuyidibanisa endaweni ye-welding. Kodwa indibaniselwano isenokungafani.Ukuwelda ngokuSoldering

Njengoninzi lwamagama ephepha lesinyithi, i-soldering kunye ne-welding zisetyenziswa ziyahambelana. Omabini la magama athathelwa ingqalelo njengeendlela zokudibanisa isinyithi. Kodwa amanyathelo kunye nobuchule buchasene. Ngokwazi la magama mabini ngokufanelekileyo, uya kufumana umbono ocacileyo wokuba yeyiphi indlela efanelekileyo kwiimfuno zakho.

Iindidi zeWelding

I-Welding yinkqubo yokuvavanya izinto ezivavanyiweyo ixesha elininzi, ubukhulu becala isinyithi apho ubushushu obuphezulu busetyenziselwa ukunyibilikisa isiseko sesinyithi kunye nokudibanisa iindawo. Inkqubo isetyenziselwa ukwenza ukudibana phakathi kwesinyithi. Kodwa endaweni yeqondo lobushushu, uxinzelelo oluphezulu lunokusetyenziswa. Kukho iintlobo ezahlukeneyo ze-welding. Uluhlu lunikwe apha ngezantsi. MIG Welding I-MIG welding yaziwa ngokuba yi-Gas Metal Arc welding. Luhlobo oludumileyo nolulula kwaye lucebise kakhulu abaqalayo. Le welding ibandakanya iintlobo ezimbini. Uhlobo lokuqala lusebenzisa ucingo oluvulekileyo okanye olungenanto kwaye emva koko kusetyenziswa isiseko sokuhamba. I-Ware welding isetyenziselwa ukudibanisa izinyithi ezahlukeneyo. Kwelinye icala, i-MIG flux core welding isetyenziselwa ukusetyenziswa ngaphandle njengoko ingafuneki nakuphi na ukuhamba kwemitha kunye nerhasi. Ukuba ungumshiseli wokuzonwabisa okanye umthandi we-DIY, le nkqubo ye-welding ilungile. Kwimeko apho, Qaphela ukuba kukho iipleyiti ezizodwa ze-MIG welding. TIG Welding Ukuwelda kwe-TIG kwaziwa ngokuba yiGas Tungsten Arc welding. Lolona hlobo ludumileyo noluguquguqukayo lwewelding. Kodwa le welding yeyenqanaba lobuchwephesha kwaye kunzima ukuyifaka. Kufuneka usebenzise izandla zakho zombini ngobuchule ukwenza i-TIG yokuwelda kakuhle. Esinye sezandla zakho sifuna ukondla intonga okanye intsimbi ofuna ukuyiwelda ngelixa esinye isandla kufuneka sibambe a TIG itotshi. Itotshi ivelisa ubushushu kunye ne-arch ukuwelda uninzi lwesinyithi zemveli kubandakanya i-aluminiyam, intsimbi, i-nickel alloys, ubhedu, i-cobalt, kunye ne-titanium. Ukunamathela kwiWelding Intonga ukuwelda ithathwa njenge Shielded Metal Arc Welding. Kule nkqubo yenkqubo, i-welding yenziwa ngendlela yakudala. Kulula kune-TIG welding kodwa kunzima kune-MIG welding. Ngokubamba i-welding, uzakufuna intonga ye-electrode welding rod. Iplasma Arc Welding Ukufakelwa kwe-Plasma Arc yitekhnoloji enononophelo kunye neyala maxesha esetyenziswa ikakhulu kwizicelo ze-aerospace apho ubukhulu besinyithi bu malunga nee-intshi ze-0.015 ezinjenge-blade ye-injini okanye itywina lomoya. Inkqubo yale welding ifana kakhulu ne-TIG welding. Welding Gas I-Welding yegesi ayifane isetyenziswe ngoku-kwiintsuku. I-TIG welding ithathe indawo yayo ubukhulu becala. Kolu hlobo lwe-welding, ioksijini kunye neasithilini ziyasetyenziswa kwaye ziyaphatheka kakhulu. Isetyenziselwa ukuhambisa iintsimbi zeemoto emva. I-Electron Beam kunye neLaser Welding Luhlobo lwe-welding olubiza kakhulu. Kodwa umphumo wale welding uza ngokuchanekileyo kakhulu. Olu hlobo luthathwa ngokuba yindlela yokuwelda ngamandla.Iindidi zeSoldering

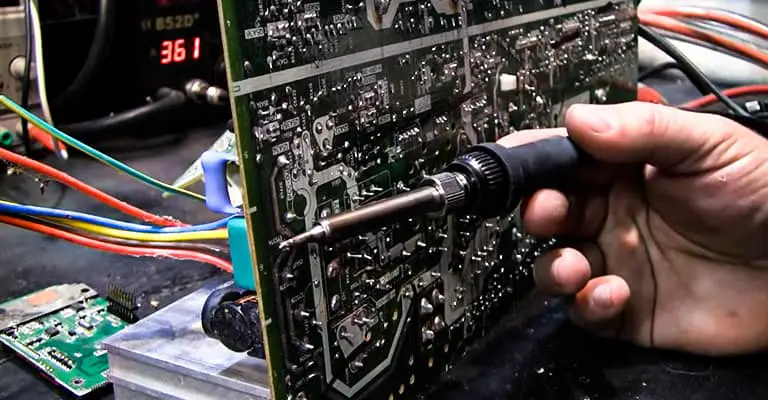

I-Solder yinkqubo yokudibanisa izinyithi ezimbini okanye nangaphezulu ngaphandle kokunyibilikisa isiseko sesinyithi. Umsebenzi wenziwa ngokubeka i-alloy eyahlukileyo ebizwa ngokuba yi-solder phakathi kweesinyithi ezimbini kwaye loo solder iyanyibilika ukujoyina. Kukho iintlobo ezahlukeneyo ze-soldering ezifana ne-soldering ethambileyo, i-soldering enzima kunye ne-brazing. Ukukhawulezisa okunzima Inkqubo ye-soldering inzima kuneyona ithambileyo. Kodwa iqhina elenziwe yile nkqubo lomelele ngakumbi. Ubushushu obuphezulu busetyenziselwa ukunyibilikisa i-solder yale soldering. Ngokwesiqhelo i-solder esetyenziswe kule nkqubo ibhedu okanye isilivere kwaye ukuze inyibilike i-blowtorch iyafuneka. Nangona indawo yokunyibilika yesilivere iphantsi kakhulu kunobhedu, ibiza kakhulu. I-soldering enzima iyaziwa njenge-soldering yesilivere xa isetyenziswe ngesilivere. Ukudibanisa isinyithi esifana nobhedu, ubhedu, okanye isilivere, kusetyenziswa islotering yesilivere. Brazing I-Brazing ikwajongwa njengohlobo lwe-solder. Kubandakanya izinto ze-solder ezinendawo yokunyibilika ephezulu kakhulu kunaleyo isetyenziswe kwi-soldering enzima kwaye ithambile. Kodwa ngokuthelekisa, iyafana ngakumbi ne-soldering enzima. Isiseko sesinyithi siyashushu kwaye kuloo ndawo ishushu, i-solder ebizwa ngokuba yibhotile yokufaka izinto ibekwa phakathi. I-solder iyanyibilika kwangoko emva kokuyibeka. Nangona kunjalo, kukho umahluko phakathi kokufaka i-soldering yesiqhelo kunye nokuhombisa.Izinto ekufuneka uziqwalasele

I-Soldering ihlala ifuna ubushushu obuphantsi njengoko isiseko sentsimbi singanyibiliki kwaye ngenxa yoko indawo yokunyibilika ye-solder kufuneka ibe ngaphantsi kwesinyithi esisiseko. Kodwa i ibhondi eyenziwe ngelotha ayomelele njengokuwelda njengakwiwelding akukho sinyithi songezelelweyo sisetyenziswayo phakathi. Isiseko sesinyithi siyanyibilika kwaye sidityanisiwe ethembekileyo. I-Welding ibhetele kwizinyithi ezinendawo ephezulu yokunyibilika. Ngokujoyina isinyithi esityebileyo, i-welding yeyona ilungileyo. Ukuba ufuna ukufakela ngokupheleleyo iziqwenga ezibini zesinyithi kuyo yonke indlela kunokuba kwindawo enye, ukuwelda ngekhe kube yinto elungileyo. Ukunyibilikisa isinyithi kwaye ukuba ufuna ukugqibezela ngaphandle komthungo, i-soldering iya kuba ngcono.

Yintoni iSoldering Soldering?

Inkqubo ye-soldering ethambileyo ithandwa kakhulu kumzi mveliso we-elektroniki kunye nemibhobho. Le ndlela isetyenziselwa ukwenza ubudlelwane phakathi kwezinto zombane kwisekethe. Kule nkqubo, i-solder yenziwe nge-tin, ilothe kunye nezinye iintlobo zentsimbi. Ukuqinisekisa ukulunga okuqinileyo, wena Ungasebenzisa into eneasidi ekuthiwa kukubhobhoza. Kwi-soldering ethambileyo, kusetyenziswe umbane okanye isinyithi esisebenzisa igesi. Ubophelelo olwenziwe yile soldering lubuthathaka kakhulu kune-solder enzima. Kodwa ngenxa yokulula kwayo, le solder iqhelekile kubaqalayo.Ngaba ukuSoldering kulunge njengeWelding?

Njengoko bekutshiwo ngaphambili, i-soldering ayinamandla njenge-welding. kodwa kwezinye izinyithi, i-soldering isebenza kakuhle njenge-welding. Nokuba ezinye izinyithi, njengobhedu, ubhedu, i-soldering yesilivere isebenza ngcono kune-welding. Kwizixhobo zombane, imibhobho yamanzi kunye nezacholo, i-soldering yenza unxibelelwano olukhawulezileyo nolicocekileyo.Yomelele kangakanani indibaniselwano yeSolder?

Uhlobo oludityanisiweyo lwe-intshi e-4-L edibeneyo ihlala iza noxinzelelo lwe-440 psi. I-solder yesilivere yamaqondo obushushu asezantsi inamandla angama-10,000 eepsi. Kodwa abathengisi besilivere banokuba namandla angaphezulu kwe-60,000 psi ekunzima ukuyifumana.Ngaba amaLungu eServer ahluleka?

Ewe, indibaniselwano ye-solder ithoba ngokuhamba kwexesha kwaye iyasilela. Eyona nto igcwele kakhulu, ibangela ulwaphulo olunamandla, ukulayisha okusisigxina kunye nokulayisha okujikelezayo kubangela ukuba ukufeza kusilele. Ukungaphumeleli kuyaziwa ngokuba kukuhamba kwaye kubangelwa ngamaqondo obushushu aphezulu. Kodwa ngenxa yezi zizathu zingasentla, inokwenzeka nakwiqondo lobushushu kwigumbi.Ngaba iBrazing yomelele kuneWelding?

Amalungu afanelekileyo obhedu anokuba namandla kunokuba isinyithi singamalungu. Kodwa azinakuba namandla ngaphezu kwamalungu adibeneyo. Ukulungiselela izinto ezisisiseko ze-welding kwaye izinto ezisisiseko zomelele kunezinto zokufaka. Izinto zokugcwalisa zinendawo yokunyibilika ephantsi. Ke iqondo lobushushu elifunekayo liphantsi, kodwa ngamandla, azifani.Ukudibanisa iVs Brazing

I-Welding ijoyina isinyithi ngokuxuba isiseko sesinyithi ngelixa, ukubhinqa kudibanisa isinyithi ngokunyibilikisa izinto zokugcwalisa. Izinto zokugcwalisa ezisetyenzisiweyo zomelele, kodwa iqondo lobushushu elifunekayo lokubhinca liphantsi kakhulu kunelo lokuwelda. Ke, ibhrashi isebenzisa amandla amancinci kune-welding. Kodwa kwezinye izinyithi ezinqabileyo, ukuhombisa kungangcono.Ukuqhawula nge-Brazing Vs

Umahluko phakathi kwabo bubushushu. Ngokwesiqhelo, kwi-soldering, izinto zokufaka zinendawo yokunyibilika engaphantsi kwe-450C. Kodwa ngobhedu, izixhobo ezisetyenzisiweyo zinendawo yokunyibilika ngaphezulu kwe-450C. I-Brazing inefuthe elincinci kwizinyithi kune-soldering. Indibaniselwano eyenziwe ngokudibanisa i-soldering yomelele kancinci kunaleyo ye-brazing.FAQ

Q: Sesiphi isinyithi esingenakuthengiswa? Iimpendulo: Ngokubanzi, zonke izinyithi zinokuthengiswa. Kodwa ezinye zinzima kakhulu kwi-solder, kungoko kungcono ukunqanda uku-soldering njenge-stainless steel, aluminium, bronze, njl. i-aluminium ye-soldering isebenzisa i-iron soldering ifuna ukhathalelo olukhethekileyo. Q: . Ngaba ikhona iglu esebenza njengejoni? Iimpendulo: Ewe, iMesoGlue yiglue yensimbi enokusetyenziselwa endaweni ye-solder. Le mveliso isebenza kubushushu begumbi kunye nakwiglu yensimbi enokuncamathelisa iziqwenga zentsimbi kunye nokungxama okungxamisekileyo kolawulo lombane. Q: Ngaba ndiyafuna ukusebenzisa i-flux kwi-solder? Iimpendulo: Ewe wena kufuneka usebenzise i-flux ukuba ayidityaniswanga kwi-solder. Ngokwesiqhelo, uninzi lwamajoni asetyenziselwa ukusetyenziswa kombane anesiseko sangaphakathi se-flux, xa kunjalo, awudingi enye.isiphelo

Ukuba ngumsebenzi wesinyithi okanye i-hobbyist, kuya kufuneka uyazi malunga nokudibanisa kunye ne-soldering. Ukuba ubathatha ngokungakhathali, ngekhe ufumane iziphumo ozilindeleyo. Nangona zifana ngokufanayo nangaphandle, ezinye zezinto eziphambili zibenze iindlela ezimbini eziphambili zokujoyina isinyithi. Eli nqaku ligxile kwiinkcukacha ezichanekileyo ze-welding, soldering, kunye ne-brazing. Ndiyathemba ukuba izakususa konke ukubhideka ngokwemigaqo, iyantlukwano, ukufana, kunye nemimandla yokusebenza.NdinguJoost Nusselder, umseki weZixhobo zeGqirha, umthengisi womxholo, kunye notata. Ndiyathanda ukuzama izixhobo ezitsha, kwaye kunye neqela lam ndiye ndenza amanqaku ebhlog anzulu ukusukela ngo-2016 ukunceda abafundi abathembekileyo ngezixhobo kunye neengcebiso zokwenza.