I-Prototyping ingumbono omuhle kakhulu wokuhlola idizayini yakho ngaphambi kokudala imodeli elungele ukukhiqiza. Amaphrinta we-3D kanye ne-CNC Machining zombili izinketho ezisebenzayo, kodwa ngayinye inezinzuzo nemikhawulo ehlukile ngokusekelwe kumapharamitha ahlukahlukene wephrojekthi. Ngakho iyiphi inketho engcono? Uma ukule conundrum, ke lesi sihloko yilokho okudingayo. Sizongena sijule kubo bobabili ubuchwepheshe futhi sixoxe ngezinto eziningi ezibalulekile ukuze sikusize unqume ukuthi yini engcono kakhulu ngokusekelwe ezidingweni zakho zephrojekthi.

Kulokhu okuthunyelwe sizomboza:

Ukuphrinta kwe-3D vs. CNC Machining: Uyini Umehluko?

Ngaphambi kokuba singene kulokho okucacisiwe, ukubamba kahle izinto eziyisisekelo kungcono kakhulu. Umehluko omkhulu phakathi kokuphrinta kwe-3D kanye ne-CNC Machining yindlela umkhiqizo wokugcina ufinyelelwa ngayo.

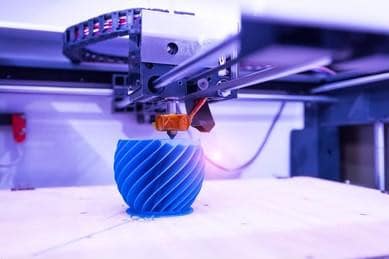

Ukuphrinta kwe-3D kuyinqubo yokukhiqiza okungeziwe. Lokhu kusho ukuthi umkhiqizo wokugcina udalwa iphrinta ye-3D ebeka phansi izendlalelo zezinto ezilandelanayo epuleti lomsebenzi kuze kufinyelelwe umumo wokugcina womkhiqizo.

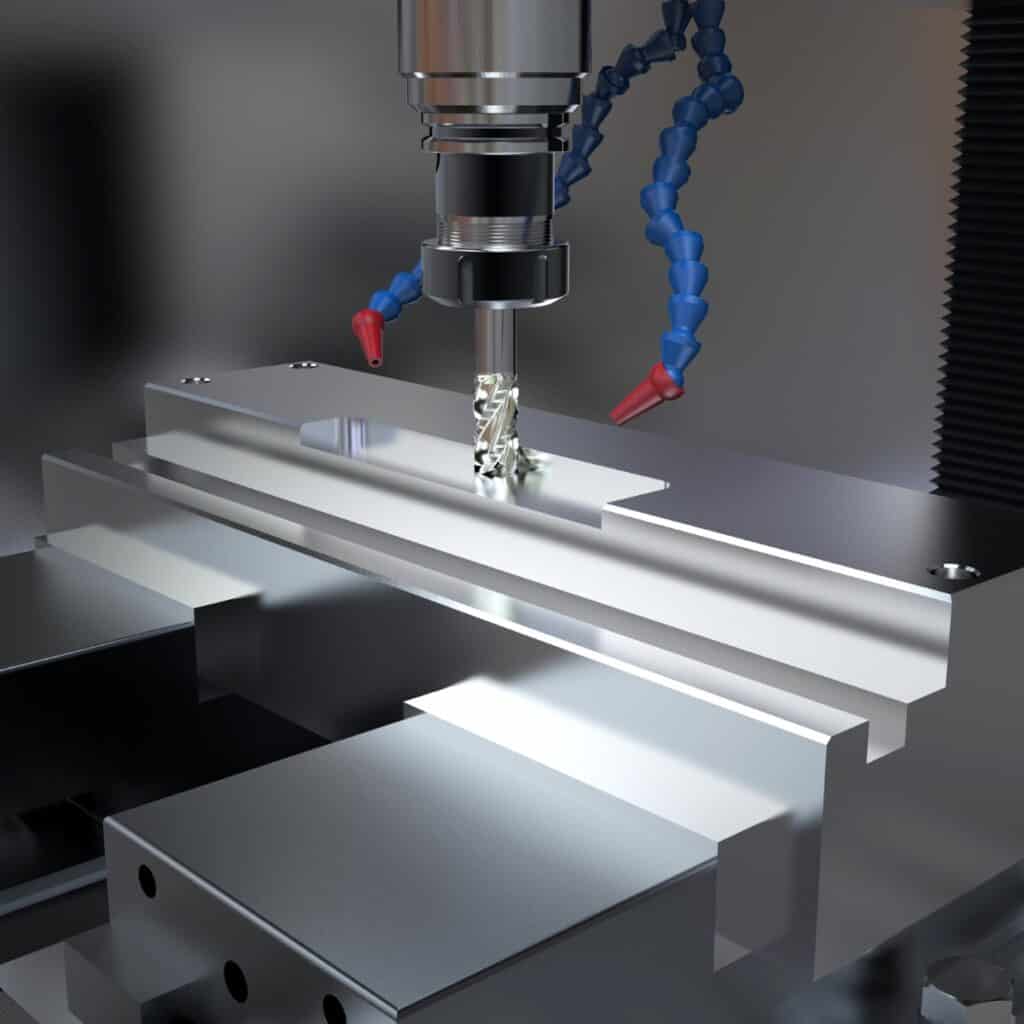

I-CNC Machining, ngakolunye uhlangothi, iyinqubo yokukhiqiza ekhiphayo. Uqala ngebhlokhi lento ebizwa ngokuthi akunalutho bese ususa umshini noma ukhiphe izinto ezizosala nomkhiqizo wokugcina.

Ungakukhetha kanjani okungcono kakhulu ngezidingo zakho zephrojekthi?

Ngayinye yalezi zindlela ezimbili zokukhiqiza zinezinzuzo ezihlukile ezimweni ezithile. Ake sibheke ngamunye ngamunye.

1. Indaba

Lapho usebenza ngensimbi, Ama-CNC Amashini ube nenzuzo ecacile. Sekukonke ukuphrinta kwe-3D kugxile kakhulu kumapulasitiki. Kunobuchwepheshe bokuphrinta be-3D obungaphrinta insimbi, kodwa ngokombono we-prototyping, bungabiza kakhulu njengoba leyo mishini yezimboni ingabiza ngaphezulu kuka-$100,000.

Okunye okubi ngensimbi yokuphrinta ye-3D ukuthi umkhiqizo wakho wokugcina awuzwakalanga njengengxenye efanayo eyenziwe ngokukhipha okungenalutho okuqinile. Ungathuthukisa amandla engxenye yensimbi ephrintiwe ye-3D ngokuphatha ukushisa, okungabangela izindleko zizonke ukuthi zikhuphuke. Mayelana nama-superalloys ne-TPU, kufanele uhambe nokuphrinta kwe-3D.

2. Izilinganiso zokukhiqiza kanye nezindleko

Uma ubheka ama-prototypes asheshayo noma amavolumu aphansi okukhiqiza (amadijithi aphansi aphindwe kabili), ukuphrinta kwe-3D ishibhile. Kumavolumu aphezulu okukhiqiza (amadijithi aphezulu aphindwe kabili kuya kumakhulu ambalwa), ukugaya i-CNC kuyindlela okufanele uhambe ngayo.

Izindleko zangaphambili zokukhiqiza okungeziwe zivame ukuba ngaphansi kunokukhiqiza okukhiphayo kuma-prototypes aphuma kanye. Uma sekushiwo, zonke izingxenye ezingadingi amajiyometri ayinkimbinkimbi zingenziwa ngendlela engabizi kakhulu kusetshenziswa imishini ye-CNC.

Uma ubheka ivolumu yokukhiqiza engaphezu kwamayunithi angama-500, ubuchwepheshe bokudala bendabuko obufana nokubumba umjovo buyonga kakhulu kunezindlela zokukhiqiza ezingezayo nezikhiphayo.

3. Ubunkimbinkimbi bomklamo

Bobabili ubuchwepheshe bunesabelo sabo sokulinganiselwa, kodwa kulo mongo, ukuphrinta kwe-3D kunenzuzo ecacile. Imishini ye-CNC ayikwazi ukuphatha amajiyometri ayinkimbinkimbi ngenxa yezinto ezinjengokufinyelela kwamathuluzi nokucaciswa, izibambi zamathuluzi, namaphoyinti okukhweza. Futhi awukwazi umshini amakhona ayizikwele ngenxa yejiyomethri yethuluzi. Ukuphrinta kwe-3D kuvumela ukuguquguquka okuningi uma kuziwa kujometri eyinkimbinkimbi.

Esinye isici okufanele sicatshangelwe ubukhulu bengxenye oyiprototyping. Imishini ye-CNC ifaneleka kangcono ukuphatha izingxenye ezinkulu. Hhayi ukuthi awekho amaphrinta e-3D laphaya angemakhulu ngokwanele, kodwa ngokombono we-prototyping, izindleko ezihlotshaniswa nephrinta enkulu ye-3D zibenza bangakwazi ukwenza umsebenzi.

4. Ukunemba kobukhulu

Ezingxenyeni ezidinga ukubekezelelana okuqinile, ukwenza imishini ye-CNC kuyisinqumo esicacile. Ukugaya kwe-CNC kungafinyelela amazinga okubekezelelana phakathi kuka-± 0.025 - 0.125 mm. Ngesikhathi esifanayo, amaphrinta e-3D ngokuvamile anokubekezelela okungu-± 0.3 mm. Ngaphandle kwamaphrinta e-Direct Metal Laser Sintering (DMLS) angakwazi ukuthola ukubekezelelana okuphansi njengokungu-± 0.1 mm, lobu buchwepheshe bubiza kakhulu ekwenzeni i-prototyping.

5. Ukuphela kwendawo

I-CNC machining iyisinqumo esicacile uma isiphetho esingaphezulu siyindlela ebalulekile. Amaphrinta e-3D angakhiqiza ukulingana okuhle nokuqeda, kodwa I-CNC Machining iyindlela okufanele uhambe ngayo uma udinga isiphetho esiphezulu ukuze uhlangane nezinye izingxenye ezinembe kakhulu.

Umhlahlandlela Owenziwe Lula Wokusiza Ukukhetha

Nali umhlahlandlela osheshayo ongakusiza ukuthi unqume phakathi kokuphrinta kwe-3D kanye nemishini ye-CNC:

- Uma ubheka i-prototyping esheshayo, efaka i-geometry eyinkimbinkimbi ye-one-off prototype noma ukukhiqiza okuncane kakhulu, khona-ke ukuphrinta kwe-3D kuzoba ukukhetha okuhle.

- Uma ubheka ukukhiqizwa okuphezulu kokwenziwa kwezingxenye ezingamakhulu ambalwa ezinamajiyometri alula, hamba ne-CNC machining.

- Uma sibheka ukusebenza ngezinsimbi, ngakho-ke ngokombono wezindleko, umshini we-CNC unenzuzo. Lokhu kubamba ngisho namanani aphansi. Nokho, ukulinganiselwa kwejometri kusasebenza lapha.

- Uma ukuphindaphinda, ukubekezelelana okuqinile, kanye nokuqedwa kwendawo okuphelele kubekwa phambili kakhulu, hamba nemishini ye-CNC.

Izwi Lokugcina

Ukuphrinta kwe-3D kusewubuchwepheshe obusha, futhi impi yakhona yokubusa emakethe isanda kuqala. Yebo, kunemishini yokunyathelisa ye-3D ebizayo futhi esezingeni eliphezulu eye yanciphisa igebe kulokho i-CNC machining ekwazi ukuyenza, kodwa ngokombono we-prototyping, ayikwazi ukucatshangelwa lapha. Asikho isixazululo esilingana nosayizi owodwa. Ukukhetha okukodwa phezu kokunye kuncike ngokuphelele ekucacisweni komklamo wephrojekthi yakho ye-prototyping.

Mayelana Nombhali:

Peter Jacobs

U-Peter Jacobs unguMqondisi Omkhulu Wezokumaketha kwa- CNC Masters. Uzibandakanya ngenkuthalo ezinqubweni zokukhiqiza futhi njalo unikela ngemininingwane yakhe kumabhulogi ahlukahlukene emishini ye-CNC, ukuphrinta kwe-3D, ukusebenzisa amathuluzi okusheshayo, ukubumba umjovo, ukuphonsa insimbi, kanye nokukhiqiza ngokujwayelekile.

Ngingu-Joost Nusselder, umsunguli we-Tools Doctor, umakethi wokuqukethwe, kanye nobaba. Ngiyakuthanda ukuzama okokusebenza okusha, futhi kanye nethimba lami ngidale izindatshana zebhulogi ezijulile kusukela ngo-2016 ukuze ngisize abafundi abathembekile ngamathuluzi namathiphu okwenza.