Ngiyakuthanda ukudala okuqukethwe kwamahhala okugcwele izeluleko zabafundi bami, wena. Angilwamukeli uxhaso olukhokhelwayo, umbono wami owami, kepha uma uthola izincomo zami zilusizo futhi ugcina uthenga okuthile okuthandayo ngesinye sezixhumanisi zami, bengingathola ikhomishini ngaphandle kwezindleko ezengeziwe kuwe. Funda kabanzi

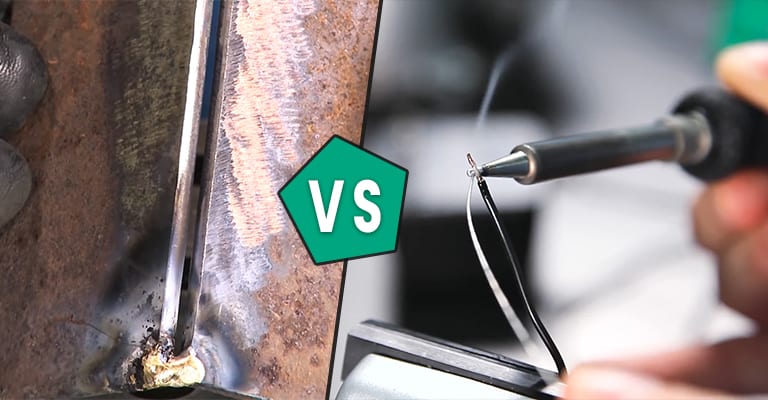

I-Brazing ne-soldering zombili izindlela ezisetshenziselwa ukuhlanganisa izingcezu ezimbili zensimbi. Bobabili babelana ngesici esiyingqayizivele esifanayo. Zombili lezi zinqubo zingasetshenziswa ukuhlanganisa izingxenye ezimbili zensimbi ngaphandle kokuncibilikisa isisekelo sensimbi. Kunalokho, sisebenzisa okokusebenza kokugcwalisa inqubo yokujoyina.

Kulokhu okuthunyelwe sizomboza:

Isebenza Kanjani I-Brazing?

Inqubo ye-brazing ayiyona inkimbinkimbi. Ekuqaleni, izingxenye zensimbi ziyahlanzwa ukuze kungabikho amafutha, upende, noma amafutha ahlala phezulu. Lokhu kwenziwa ngokusebenzisa i-sandpaper ecolekile noma uboya bensimbi. Ngemva kwalokho, zibekwe ngokumelene nomunye. Imvume ethile inikezwa ukusiza isenzo se-capillary yezinto zokugcwalisa. Ukusetshenziswa kwe-flux kwenziwa ukuze kuvinjelwe i-oxidation ngesikhathi sokushisa. Iphinde isize ingxubevange yokugcwalisa encibilikisiwe imanzise izinsimbi ukuze zihlanganiswe kahle. Isetshenziswa ngendlela yokunamathisela emajoyini ukuze ibrazed. I impahla ye-flux ngoba i-brazing ngokuvamile i-borax. Ngemuva kwalokho, izinto zokugcwalisa ngendlela yenduku yokubopha zifakwa ekuhlanganyeleni ukuze ziboshwe. Induku iyancibilika ngokufaka ukushisa okuphezulu kuyo. Uma sezincibilikile zigelezela ezingxenyeni ezizohlanganiswa ngenxa yesenzo se-capillary. Ngemva kokuba zincibilike kahle futhi ziqinisiwe inqubo iyenziwa.

Isebenza kanjani i-Soldering?

The inqubo ye-soldering ayihlukile kangako kunqubo yokubhula. Nalapha futhi, umthombo wokushisa usetshenziselwa ukufaka ukushisa ezinsimbi eziyisisekelo okufanele zihlanganiswe. Futhi, njengenqubo yokubhula izingxenye ezizohlanganiswa noma izinsimbi eziyisisekelo azincibiliki. I-filler metal iyancibilika futhi ibangele ilunga. Umthombo wokushisa osetshenziswa lapha ubizwa ngokuthi i-soldering iron. Lokhu kusebenzisa inani elilungile lokushisa ezinsimbi eziyisisekelo, isigcwalisi, kanye nezinsimbi ukuhamba. Okubili izinhlobo zezinto eziguquguqukayo zisetshenziswa kule nqubo. I-organic kanye ne-inorganic. Ukuguquguquka kwezinto eziphilayo akunayo imiphumela elimazayo. Ngakho-ke asetshenziswa ezimweni ezibucayi kakhulu njengezifunda.

Ingabe Kufanele Ufake I-Solder?

Ngaphambi kokunquma ukuthi iyiphi inqubo ozoyisebenzisa kunezinto ezimbalwa okufanele uzikhumbule.Iphuzu Elingenzeka Lokuhluleka

Ngokujwayelekile emalungeni e-solder, izinto zokugcwalisa zibuthakathaka kakhulu kunezinsimbi eziyisisekelo. Ngakho-ke uma ingxenye edayisiwe igcizelelwe kakhulu phakathi nenkonzo khona-ke iphuzu lokwehluleka cishe liyoba i-soldered joint. Ngakolunye uhlangothi, inhlanganisela eboshwe kahle ayisoze yahluleka ngenxa yobuthakathaka bezinto zokugcwalisa. Isizathu esiyinhloko sokuthi amalunga e-brazed ahluleka kungenxa yengxube ye-metallurgical eyenzeka emazingeni okushisa aphezulu kakhulu. Ngakho-ke ukwehluleka kwenzeka ikakhulukazi kusisekelo sensimbi ngaphandle kwelunga ngokwalo. Ngakho-ke kufanele uhlaziye lapho ingxenye oyijoyinile izogcizelelwa kakhulu. Ngemuva kwalokho, ungakhetha inqubo enciphisa amathuba okuhluleka.Ukukhathala Ukumelana

Ijoyinti elenziwe inqubo yokubhula lingamelana nokucindezeleka okuqhubekayo nokukhathala ngenxa yebhayisikili eshisayo noma ukushaqeka komshini. Okufanayo akukwazi ukushiwo kodwa ngokuhlanganyela okudayisiwe. Ijwayele ukwehluleka lapho ibhekene nokukhathala okunjalo. Ngakho-ke kufanele ucabangele ukuthi hlobo luni lwezimo ilunga lakho elingase likwazi ukubekezelela.Isidingo Somsebenzi

Uma inhloso yakho ehlosiwe yengxenye ehlanganisiwe idinga ukuthi ibambe ukucindezela okuningi kuyindlela efanele yokuhamba. Ivamise ukusetshenziswa kumaphrojekthi afana nezingxenye zezimoto, izinjini zejethi, amaphrojekthi e-HVAC, njll. Kodwa i-soldering nayo inezakhiwo ezihlukile ezifunwa kakhulu. Izinga layo lokushisa eliphansi lokucubungula liyenza ilungele ukusetshenziswa nezingxenye ze-elekthronikhi. Ezicini ezinjalo ezisingatha inani elikhulu lokucindezeleka akuyona into ekhathaza kakhulu. Ngenxa yalokhu, ngisho i-flux esetshenziswa ekuthengiseni i-electronics yehlukile. Ngakho-ke ngaphambi kokunquma ukuthi iyiphi inqubo ozoyisebenzisa ungase uthande ukucabangela ukuthi yiziphi izakhiwo ezifiselekayo esimweni sakho sokusebenzisa. Ngokusekelwe kulokho ungakwazi ukunquma ukuthi iyiphi ewufanelekela umsebenzi wakho.Isiphetho

Nakuba i-brazing kanye ne-soldering kungase kube izinqubo ezifanayo kunomehluko othile ohlukile. Inqubo ngayinye inezakhiwo ezihlukile ezifunwa izinhlelo zokusebenza ezihlukahlukene. Ukuze unqume ukuthi iyiphi efanelana kangcono nomsebenzi wakho kufanele uhlaziye ngokucophelela futhi uthole ukuthi yiziphi izakhiwo ezibalulekile kuphrojekthi yakho.Ngingu-Joost Nusselder, umsunguli we-Tools Doctor, umakethi wokuqukethwe, kanye nobaba. Ngiyakuthanda ukuzama okokusebenza okusha, futhi kanye nethimba lami ngidale izindatshana zebhulogi ezijulile kusukela ngo-2016 ukuze ngisize abafundi abathembekile ngamathuluzi namathiphu okwenza.