I-soldering aluminium ingaba yinkohliso uma ungakwenzanga ngaphambili. I-aluminium oxide izokwenza imizamo yakho eminingi ibe yize. Kepha, uma usunomqondo ocacile wenqubo, iba lula impela. Yilapho ngingena khona. Kodwa ngaphambi kokuthi singene kulokho, ake sibheke izisekelo ezithile.

Kuyini ukugoqa?

Ukugcoba kuyindlela yokuhlanganisa izingcezu ezimbili zensimbi ndawonye. Insimbi e-soldering iyancibilikisa insimbi enamathisela imisebenzi emibili yensimbi noma izifunda ezithile ezimakiwe. I-Solder, insimbi encibilikisiwe, iphola ngokushesha okukhulu ngemuva kokukhipha umthombo wokushisa futhi iqinise ukugcina izingcezu zensimbi zisendaweni. Iqinile kakhulu i-glue yensimbi.

Izinsimbi ezithambile ngokuthe xaxa zithengiswa ukuze zihlangane. Izinsimbi eziqinile zivame ukufakwa nge-welding. Ungakwazi zenzele insimbi yakho yemisebenzi yakho ethile futhi.

I-Solder

Kuyinhlanganisela yezinto ezahlukahlukene zensimbi futhi isetshenziselwa ukugoqa. Ezinsukwini zokuqala, i-solder yayenziwa ngothini nomthofu. Kulezi zinsuku, izinketho ngaphandle kokuhola zisetshenziswa kakhulu. Izintambo zokunamathisela imvamisa iqukethe i-tin, ithusi, isiliva, i-bismuth, i-zinc, ne-silicon.

I-Solder inendawo encibilika kancane futhi iyaqina ngokushesha. Enye yezidingo ezibalulekile ze-solder yikhono lokuqhuba ugesi njengoba i-soldering isetshenziswa kakhulu ekwakheni amasekethe.

ageleze

I-Flux ibalulekile ekwakheni amalunga we-quality solder. I-Solder ngeke imanzise ijoyinti kahle uma kunengubo ye-oxide yensimbi. Ukubaluleka kokugeleza kungenxa yekhono layo lokuvimbela ama-oxide ensimbi ekwakheni. Izinhlobo zokugeleza okusetshenziswa kuma-solders kagesi ezisetshenziswa kakhulu zivame ukwenziwa nge-rosin. Ungathola i-rosin engahluziwe ezihlahleni zikaphayini.

I-Soldering Aluminium

Akukaze kufane nokufaka okwejwayelekile. Ukuba yinsimbi yesibili ethambile kakhulu emhlabeni futhi enokusebenza okukhulu kokushisa, izinsimbi ze-Aluminium zivame ukuba mncane kakhulu. Ngakho-ke, noma beza ne-ductility enhle, ukushisa ngokweqile kusazobamba futhi / noma kukukhubaze.

Amathuluzi Afanele

Ngaphambi kokuqala, kubaluleke kakhulu ukuqinisekisa ukuthi unamathuluzi adingekayo we-solder aluminium. Njengoba i-aluminium inendawo yokuncibilika ephansi engaba ngu-660 ° C, uzodinga i-solder enephuzu lokuncibilika eliphansi. Qiniseka ukuthi i-soldering iron yakho yenzelwe ukujoyina i-aluminium.

Enye into ebalulekile okufanele ube nayo ukugeleza okuhloselwe ukugoqa i-aluminium. I-Rosin fluxes ngeke nje isebenze kuyo. Iphuzu lokuncibilika lokugeleza kufanele futhi lifane nensimbi ye-soldering.

Uhlobo lwe-Aluminium

I-aluminium emsulwa ingathengiswa kodwa njengoba kuyinsimbi eqinile, akulula ukusebenza nayo. Imikhiqizo eminingi ye-aluminium oyitholayo ingama-aluminium alloys. Iningi lazo lingathengiswa ngendlela efanayo. Kodwa-ke, kukhona okumbalwa okuzodinga usizo lochwepheshe.

Uma kwenzeka umkhiqizo we-aluminium onawo umakwe ngohlamvu noma inombolo, kufanele ubheke imininingwane bese uhambisana nayo. Ama-alloys e-Aluminium aqukethe i-1% ye-magnesium noma i-5% ye-silicon kulula ukuyi-solder.

Ama-alloys anenani elingaphezulu kwalokhu azoba nezimpawu zokumanzisa okungalungile. Uma i-alloy inephesenti eliphezulu lethusi ne-zinc kuyo, izoba nezici ezimbi zokufaka okokunamathisela ngenxa yokungena okusheshayo kwe-solder nokulahleka kwezakhiwo zensimbi eyisisekelo.

Ukubhekana ne-Aluminium oxide

I-soldering aluminium ingaba nzima uma iqhathaniswa nezinye izinsimbi. Kungakho ulapha phela. Endabeni yama-alloys e-aluminium, agqokelwe ungqimba lwe-aluminium oxide ngenxa yokuhlangana nomoya.

I-Aluminium oxide ayinakuthengiswa, ngakho-ke kuzofanela uyisule ngaphambi kokwenza kanjalo. Futhi, khumbula ukuthi lawa ma-oxide ensimbi azoguquka ngokushesha okukhulu lapho ehlangana nomoya, ngakho-ke ukuguqulwayo kufanele kwenziwe ngokushesha okukhulu.

Ungayisusa kanjani i-Aluminium nge-Soldering Iron | Izinyathelo

Manje njengoba ubanjwe yizisekelo, kufanele ulungele ukuqhubeka nokunamathisela ngomthofu. Landela lezi zinyathelo ngokucophelela ukuze uqiniseke ukuthi uzenza kahle.

Isinyathelo-1: Ukushisa Izinyathelo Zakho Zensimbi Nezokuphepha

Kuzothatha isikhashana ukuthola i-soldering iron yakho kushisa elifanele. Ngingasikisela ukuthi ugcine indwangu emanzi noma isiponji ukuhlanza i-ayina noma iyiphi i-solder eyeqile. Gqoka imaski yokuphepha, izibuko kanye namagilavu ngenkathi ukuyo.

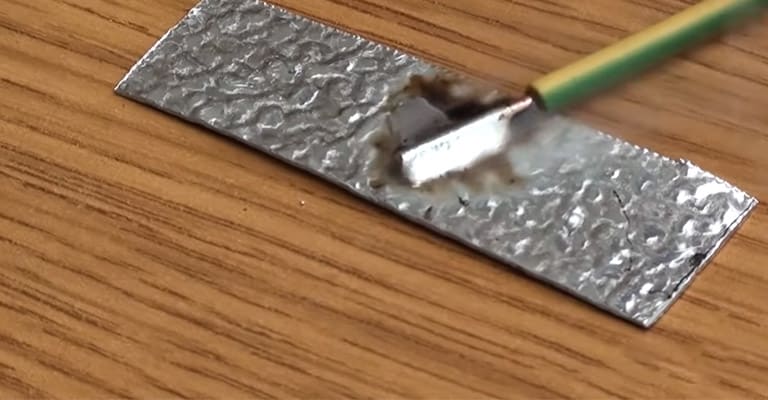

Isinyathelo-2: Ukususa ungqimba lwe-Aluminium oxide

Sebenzisa ibhulashi lensimbi ukususa ungqimba lwe-aluminium oxide kusuka ku-aluminium. Uma usebenzisa i-aluminium endala ene-oxidization esindayo, kufanele usike noma usule usebenzisa i-acetone ne-isopropyl alcohol.

Isinyathelo-3: Ukufaka i-Flux

Ngemuva kokuhlanza izingcezu, faka i-flux kanye nezindawo ofuna ukuzijoyina. Ungasebenzisa ithuluzi lensimbi noma nje induku ye-solder yohlelo lokusebenza. Lokhu kuzomisa i-aluminium oxide yokwakha kanye nokudweba i-iron solder ohlangothini olude lwejoyini.

Isinyathelo-4: Ukuqinisa / Ukubeka

Lokhu kuyadingeka uma uhlanganisa izingcezu ezimbili ze-aluminium ndawonye. Zibambe esimweni ofuna ukuzijoyina. Qiniseka ukuthi izingcezu ze-aluminium zinegebe elincane phakathi kwazo lapho zibambelela ukuthi i-iron solder igeleze.

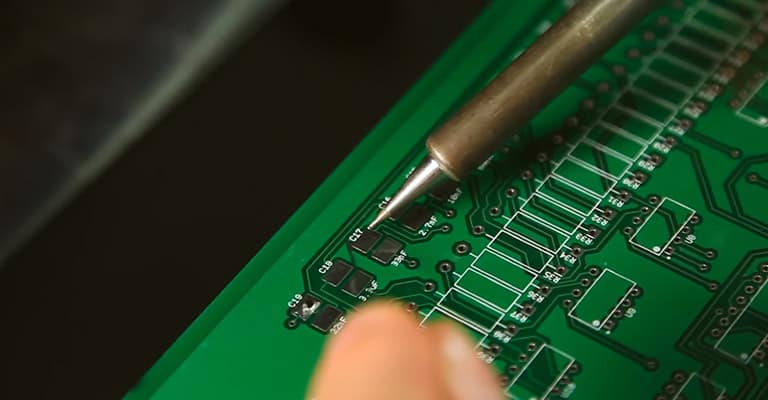

Isinyathelo-5: Ukufaka Ukushisa Kucezu Lomsebenzi

Ukushisa insimbi kuzovimbela i- "Cold join" eqhekeka kalula. Sishisa izingxenye zezingcezu eziseduze nokujoyina ngensimbi yakho ye-soldering. Ukufaka ukushisa endaweni eyodwa kungadala ukuthi ukuhamba futhi i-solder ishise kakhulu, ngakho-ke, qiniseka ukuthi uqhubeka uhambisa umthombo wakho wokushisa kancane. Ngaleyo ndlela indawo ingashiswa ngokulinganayo.

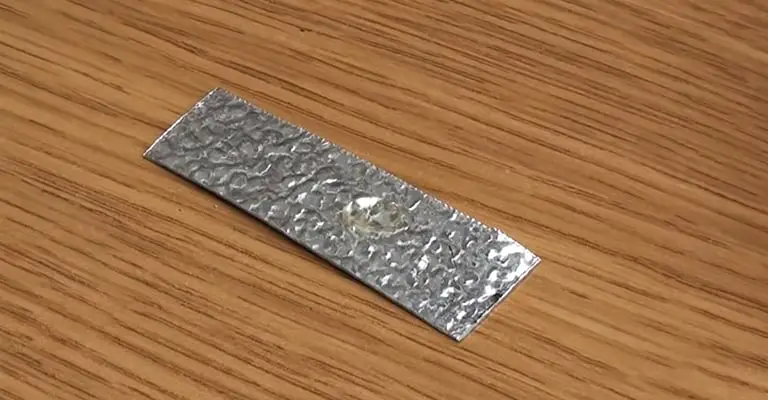

Isinyathelo-6: Ukubeka iSolder kuJoint nokuQeda

Sishisa i-solder yakho ize ithambe. Bese uyisebenzisa kujoyini. Uma inganamatheli nge-aluminium, ungqimba lwe-oxide kungenzeka luguquliwe. Uzodinga ukuxubha nokuhlanza izingcezu futhi ngiyesaba. Kuzothatha imizuzwana embalwa kuphela ukuthi i-solder yome. Ngemuva kokumisa, susa ukugeleza okusele nge-acetone.

Isiphetho

Konke mayelana nokuqonda inqubo uma kukhulunywa nge-soldering aluminium. Susa ungqimba lwe-aluminium oxide ngaphezulu ngensimbi noma nge-sanding. Sebenzisa i-soldering iron efanele, i-solder, ne-flux. Futhi, sebenzisa indwangu emanzi uku susa i-solder eyengeziwe ukuqeda okuhle. O, futhi ngaso sonke isikhathi sebenzisa izindlela zokuphepha.

Hhayi-ke unayo. Ngiyethemba manje usuqonde ukuthi ungayenza kanjani i-solder aluminium. Manje singena eworkshop, siya.

Ngingu-Joost Nusselder, umsunguli we-Tools Doctor, umakethi wokuqukethwe, kanye nobaba. Ngiyakuthanda ukuzama okokusebenza okusha, futhi kanye nethimba lami ngidale izindatshana zebhulogi ezijulile kusukela ngo-2016 ukuze ngisize abafundi abathembekile ngamathuluzi namathiphu okwenza.