Ngiyakuthanda ukudala okuqukethwe kwamahhala okugcwele izeluleko zabafundi bami, wena. Angilwamukeli uxhaso olukhokhelwayo, umbono wami owami, kepha uma uthola izincomo zami zilusizo futhi ugcina uthenga okuthile okuthandayo ngesinye sezixhumanisi zami, bengingathola ikhomishini ngaphandle kwezindleko ezengeziwe kuwe. Funda kabanzi

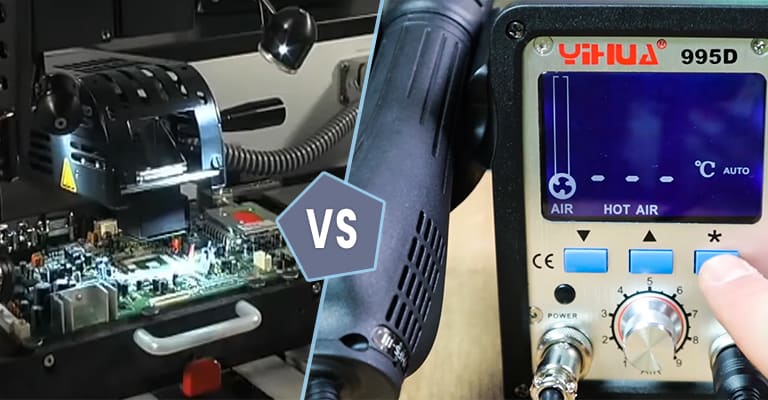

Iziteshi zokuphinda zisebenze kanye neziteshi zokuhlanganisa zingamadivayisi asetshenziselwa ukuhlanganisa nokulungisa amabhodi esekethe aphrintiwe(PCB). Lawa madivaysi aqukethe izingxenye ezimbalwa ezenza imisebenzi ethile. Asetshenziswa kakhulu kumalabhorethri ahlukahlukene, ama-workshops, izimboni, ngisho nokusetshenziswa kwasekhaya ngabathanda ukuzilibazisa.

Kulokhu okuthunyelwe sizomboza:

Siyini Isiteshi Sokusebenza Kabusha?

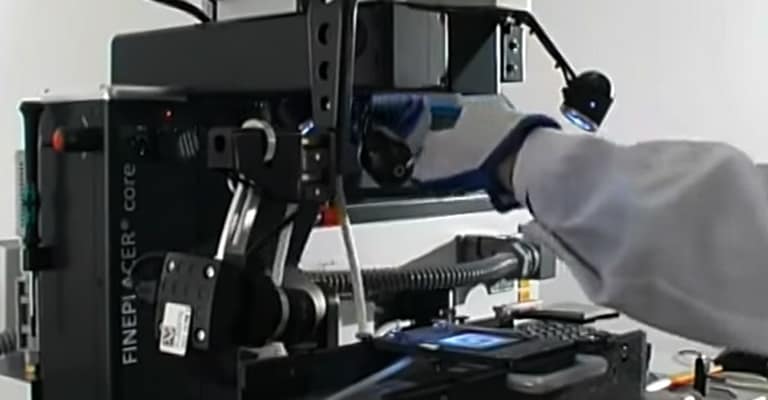

Igama elithi rework, lapha, lisho inqubo yokucwenga kabusha noma ukulungisa amabhodi esekethe aphrintiwe nge-elekthronikhi. Lokhu kuvame ukubandakanya ukudayiswa kwe-soldering kanye nokuphinda kudayiswe izingxenye ze-elekthronikhi ezifakwe phezulu. Isiteshi sokusebenza kabusha siwuhlobo lwebhentshi lomsebenzi. Leli bhentshi lokusebenzela linawo wonke amathuluzi adingekayo afakwe kulo. I-PCB ingafakwa endaweni efanele futhi umsebenzi wokulungisa ungenziwa ngamathuluzi afakwe esiteshini.

Siyini Isiteshi Sokushisisa?

A isiteshi se-soldering iyithuluzi elisebenza ngezindlela eziningi elingasetshenziswa ukudayisa izingxenye ze-elekthronikhi ezihlukahlukene. Uma kuqhathaniswa i-soldering iron i-soldering station ivumela ukulungiswa kwezinga lokushisa. Lokhu kuvumela idivayisi ukuthi ibhekane nezimo ezihlukahlukene zokusetshenziswa. Le divayisi ngokuyinhloko iqukethe amathuluzi amaningi e-solder axhuma kuyunithi eyinhloko. Lawa madivaysi athola ukusetshenziswa kakhulu emkhakheni wezogesi nobunjiniyela bukagesi. Ngisho nangaphandle kwezingcweti, abathandi bokuzilibazisa abaningi basebenzisa lawa madivaysi kumaphrojekthi ahlukahlukene e-DIY.

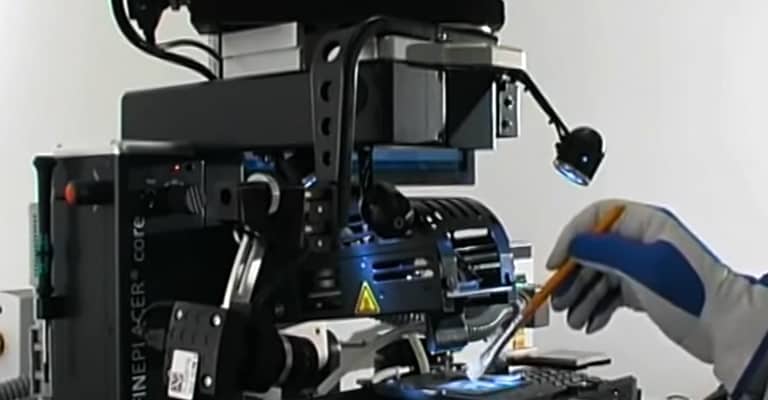

Ukwakhiwa Kwesiteshi Sokusebenza Kabusha

Isiteshi sokusebenza kabusha sakhiwa kusetshenziswa izakhi eziyisisekelo ezisiza ngayinye emsebenzini wokulungisa.

Ukwakhiwa Kwesiteshi Sokushisisa

Isiteshi sokunamathisela sakhiwa kusetshenziswa izingxenye ezihlukahlukene ezisebenza ndawonye ukwenza umsebenzi ngendlela efanele.

Ukusetshenziswa Kwesiteshi Sokusebenza Kabusha

Ukusetshenziswa okuyinhloko kwesiteshi sokusebenza kabusha ukulungisa amabhodi esekethe aphrintiwe nge-elekthronikhi. Lokhu kungase kudingeke ngenxa yezizathu eziningi.

Ukusetshenziswa kwe-Soldering Station

Iziteshi zokuthengisa zithola ukusetshenziswa okubanzi ezindaweni ezisukela kumalabhorethri angochwepheshe be-elekthronikhi kuya kuma-DIY hobbyists.

Isiphetho

Kokubili i-rework station kanye ne-soldering station kukhona amadivaysi awusizo kakhulu lokho kungaba usizo ngenxa yezizathu eziningi. Azivamile nje kuphela ezitolo ezilungisa izinto zikagesi nasemalabhorethri kodwa nasemakhaya abantu abaningi abazilibazisa. Uma ubheka ukwakha amabhodi esekethe aphrintiwe kagesi ngokwezifiso zakho noma uxhume izinto kumasekhethi bese u-soldering okukhethwa kukho okulungile kuwe. Kodwa uma umsebenzi wakho ugxile kakhulu ekulungiseni kunokuya esiteshini sokusebenza kabusha.Ngingu-Joost Nusselder, umsunguli we-Tools Doctor, umakethi wokuqukethwe, kanye nobaba. Ngiyakuthanda ukuzama okokusebenza okusha, futhi kanye nethimba lami ngidale izindatshana zebhulogi ezijulile kusukela ngo-2016 ukuze ngisize abafundi abathembekile ngamathuluzi namathiphu okwenza.