Ngiyakuthanda ukudala okuqukethwe kwamahhala okugcwele izeluleko zabafundi bami, wena. Angilwamukeli uxhaso olukhokhelwayo, umbono wami owami, kepha uma uthola izincomo zami zilusizo futhi ugcina uthenga okuthile okuthandayo ngesinye sezixhumanisi zami, bengingathola ikhomishini ngaphandle kwezindleko ezengeziwe kuwe. Funda kabanzi

Izinsimbi zokugcoba zibe yisixazululo esihle kuzo zonke izinhlobo zezinkinga ezihlangene phakathi kwezinsimbi noma ngisho Welding plastic nge solder. Izithuthi, amapayipi, kanye namabhodi wesifunda kagesi ngamasimu ambalwa nje anokusetshenziswa okubanzi kwensimbi ye-soldering. Abasebenzisi bayayithanda lapho bencibilikisa i-solder ngensimbi yabo yoku-soldering futhi balungise okuthile ebebekhathazekile ngakho. Kepha into eyodwa engathandwa muntu yinsimbi yokungcola engcolile. I-iron soldering engahlanzekile ayiyinhle kangako ukuyibuka futhi okubaluleke kakhulu, ayisebenzi kahle ekuncibilikiseni i-solder. Kulo mhlahlandlela, sizokutshela konke mayelana nokuhlanza i-iron soldering bese sabelana ngamathiphu athile namasu endleleni.

Kulokhu okuthunyelwe sizomboza:

Kungani i-Soldering Iron Iba Ngcolile?

Esinye salezo zizathu ukuthi amathiphu we-soldering iron ahlangana nezinhlobo ezahlukahlukene zezinto bese eziqoqa njengezikhathi ezisele zensalela. Futhi, ukugqwala kuyinkinga evamile ngazo zonke izinsimbi futhi i-soldering iron ayihlukile. Uma u susa i-solder ngensimbi yoku-soldering kusuka ebhodini lesifunda, lapho-ke futhi kuzoba imbangela yokuthi i-soldering iron yakho ingcole.

Ungayihlanza kanjani i-Soldering Iron- Uhlu lwama-Paradigms

Ngaphandle kwethiphu yensimbi, i-ironering iron nayo inesisisekelo sensimbi, ipulasitiki noma isibambo sokhuni, nentambo yamandla. Izinhlobo ezahlukahlukene zokungcola zizoqoqeka ngokuhamba kwesikhathi kuzo zonke lezi zingxenye. Sizokutshela ngokuhlanza lezi zingxenye ngokwezigaba.

Ukuqapha

I-soldering ingaba yingozi futhi ibe yingozi kuwo wonke umuntu oqalayo. Ukuhlanza insimbi nakho kunengxenye yako efanele yengozi. Sincoma ukusebenzisa izibuko zokuphepha namagilavu ngenkathi uhlanza. Kungcono ukuba nesistimu yokuphefumula kahle ukuze kukhishwe intuthu. Cela usizo lochwepheshe uma ungazethembi uwedwa.Hlanza Izingxenye Ezingashisi

Sebenzisa ucezu lwendwangu noma ibhulashi ukususa ngokuyinhloko uthuli noma ukungcola kusuka kukhebula lamandla nesibambo sensimbi ye-soldering. Ngemuva kwalokho, sebenzisa ucezu lwendwangu olufakwe emanzini ukuqeda amabala anenkani noma izinto ezinamathelayo esibambo nasentanjeni yamandla. Ungakhohlwa ukomisa insimbi ngokuphelele ngaphambi kokufaka ikhebula futhi.

Ungayihlanza Kanjani Ithiphu Yensimbi Yokugcoba?

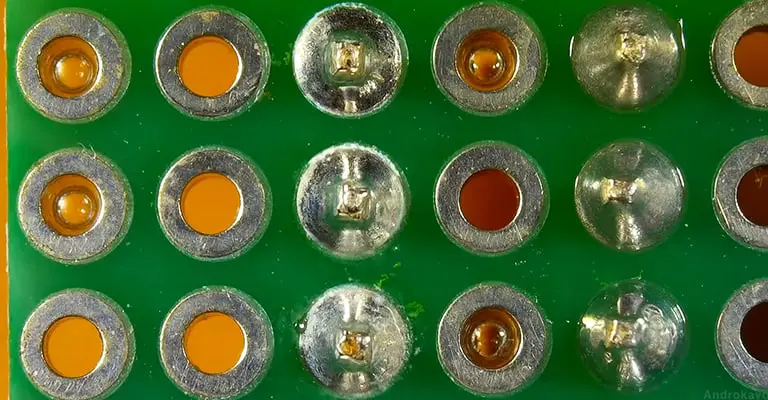

Ukususa ukungcola kusuka ekugcineni kwensimbi oku-soldering kuyinselele enkulu kunezinye izingxenye. Njengoba kunezinhlobo ezahlukahlukene zokungcola nemfucumfucu ezingenza ithiphu ingcolile, sizokutshela izindlela ezahlukahlukene zokuzinakekela. Kulesi sigaba, sizokwemboza zonke izinhlobo zokungcola okungenayo i-oxidizing bese siqhubeka nensimbi ye-soldering ene-oxidized ngokuhamba kwesikhathi.

Ukwenza ithiphu nge-Iron Tip

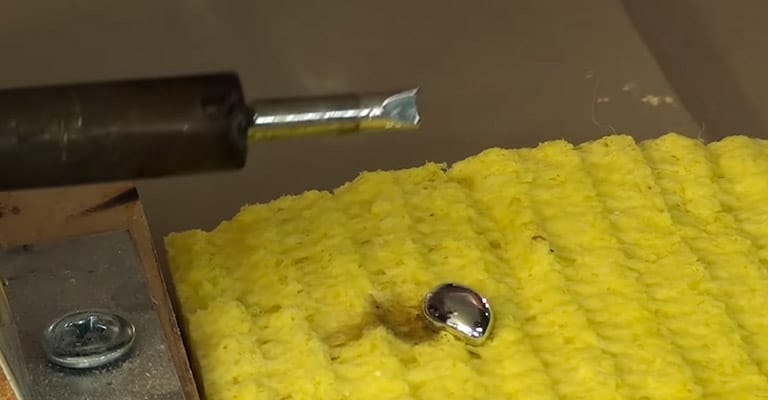

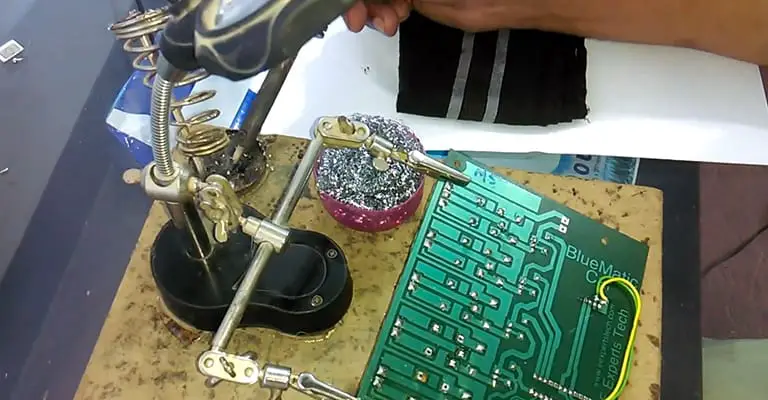

Ukwenza i-tinning, njengoba igama liphakamisa, kuyinqubo yokusebenzisa i-tin. Kulesi simo esithile, ukufaka i-tinning kubhekisa enqubweni yokufaka isembozo se-tin esezingeni eliphezulu ngaphezulu kwethiphu lensimbi yensimbi ye-soldering. Kepha ngaphambi kokuba uqale ukwenza lokhu, sincoma ukusebenzisa izibuko zokuphepha. Shisisa i-iron soldering ufake izibuko zokuphepha bese usebenzisa ithini le-soldering elisezingeni eliphakeme ukufaka uthini omncane nongqimba lwethini esicijeni sensimbi. Ukwenza lokhu kuzosiza ukuvimbela ukugqwala ngakho-ke sikuncoma ngemuva kokuqeda wonke umsebenzi we-soldering.

Sebenzisa i-Alloy Cleaners

Ngokwengeziwe, ungasebenzisa ama-alloy cleaners kwinsimbi ye-soldering nayo ekususeni ukungcola okungenayo i-oxidizing. Ngemuva kokuthi wenze izinyathelo zangaphambilini, sebenzisa kancane ukuvumela ukuhlanza kwendwangu ye-microfiber bese uyisebenzisa ukuhlanza i-iron soldering. Gcoba indwangu kahle nangokucindezela i-ayina ukuze uyihlanze kangcono.

Ungayihlanza Kanjani i-Oxidized Soldering Iron Tip?

I-oxidizing inqubo yokwakha ukugqwala ezinsimbi. Kuyinqubo engokwemvelo lapho zonke izinsimbi zidlula khona. Esikhathini eside, izinsimbi zithola ukusebenza kwamakhemikhali nomoya-mpilo womoya bese zakha leyo ngubo emnyama. Kepha leyo nqubo yokwakha ukugqwala ishesha kakhulu lapho kukhona ukushisa futhi yilokho kanye okwenzekayo uma kwenzeka insimbi yoku-soldering. Uma ungayihlanza ngemuva kokuyisebenzisa njalo, ithiphu lensimbi lizothola i-oxidized bese kwakhiwa ukugqwala.

Ungayihlanza kanjani i-Soldering Iron ngeFlux?

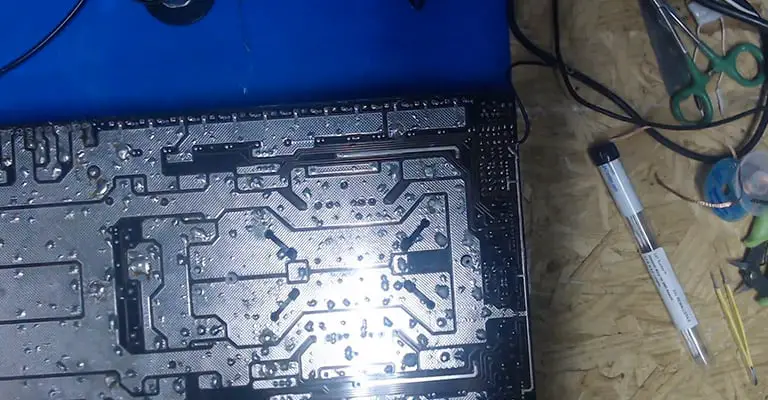

Ukuze ususe i-oxidation emaphakathi, kufanele ufake isicelo ukuhamba phezu kwethiphu yensimbi yokunamathisela ngenkathi ishisa insimbi cishe kuma-degrees Celsius angama-250. I-Flux yinto yamakhemikhali lokho kuhlala njengejeli ekamelweni lokushisa. Uma ihlangana nethiphu yensimbi eshisayo equkethe ukugqwala,kuncibilikisa ukugqwala. Imvamisa, uzothola lawa ma-gel e-soldering flux emabhokisini amancane. Shisisa i-soldering iron bese ufaka ithiphu ngaphakathi kwejeli. Izodala intuthu ngakho qiniseka ukuthi ugcina umoya ongcono. Ngemva kwesikhashana, khipha ithiphu lensimbi kujeli, futhi usebenzisa izinhlelo zokuhlanza ezomile, hlambulula ukugqwala. Ungasebenzisa uvolo wethusi njengesicoci esomile. Okwamanje, ezinye zezintambo ze-solder ziza ne-flux core. Uma uncibilikisa ucingo lwe-solder, i-flux iyaphuma futhi ithintane nethiphu yensimbi. Njenganoma iyiphi enye intambo yokugoqa, ncibilikisa lezo zintambo futhi ukugeleza ngaphakathi kuzokusiza ukuthi udambise i-oxidation. Bese, uyihlanze usebenzisa uvolo wethusi noma izihlanzi zethiphu ezizenzakalelayo.

Ukususa Ukuxhuma Okunamandla

Lapho i-soldering iron yakho ine-oxidation enzima esicelweni sayo, amasu amnene ngeke asebenze ngokwanele ekuyisuseni. Udinga into ekhethekile ebizwa ngeTip Tinner. I-Tip Tinner nayo ijeli eyinkimbinkimbi yamakhemikhali. Indlela yokuhlanza icishe ifane naleyo emnene. Vula i-iron soldering bese uyishisa ibe ngama-250 degrees Celsius. Bese, cwilisa ichopho lensimbi yokufaka phakathi kwejel. Yibambe lapha imizuzwana embalwa uzobona amakhemikhali avela ku-tip tinner ancibilika azungeze ichopho. Ngemuva kwesikhashana, thatha okwethu kusuka kujel bese uhlanza ithiphu usebenzisa uboya bezintambo.

Izinsalela ze-Flux

Njengoba ukususa i-oxidation emnene kusuka ku-soldering iron kudinga ukugeleza, kungokwemvelo ukuthi kuzoba khona izinsalela ze-flux. Kwesinye isikhathi, le nsalela izohlala entanyeni yethiphu yensimbi ye-soldering. Kubonakala njengokumboza okumnyama nxazonke. Njengoba kungathinti amandla we-soldering noma wokushisa we-tip yensimbi ngakho-ke akukho lutho ongakhathazeka ngalo.

Izinto Okufanele Uzigweme Ngesikhathi Sokuhlanza

Iphutha elijwayelekile elenziwa abasebenzisi abaningi abangenalwazi ukusebenzisa i-sandpaper ukuhlanza ichopho lensimbi le-soldering. Siluleka ngokuqinile ngakho ngoba i-sandpaper isusa ukungcola ngokubola ithiphu lensimbi. Futhi, musa ukuhlanza ukucucuza usebenzisa noma iyiphi indwangu ejwayelekile. Sebenzisa izipanji noma uvolo wethusi.

Amathiphu wokugcina i-Soldering Iron ihlanzekile

Indlela engcono kakhulu yokugcina into ihlanzekile ukuyihlanza njalo, hhayi nje ngemuva kokuthola ukungcola okuningi kuyo. Lokhu kusebenza kukho konke. Endabeni yensimbi ye-soldering, uma uhlanza ithiphu yensimbi ngokushesha ngemuva kokusebenzisa, ukungcola ngeke kuqoqwe. Ukuze wehlise ijubane inqubo ye-oxidizing, ungazama ukufaka ithiphu yensimbi ngemuva kwakho konke ukusetshenziswa.

imibuzo ejwayelekile ukubuzwa

Q: Ingabe kuyindlela enhle yokuhlanza amathiphu wensimbi we-soldering ngokukhuhla? I-Ans: Akunjalo Empeleni. Ukuhlikihla nganoma iyiphi enye insimbi kungasusa okunye okwexhuma emzimbeni kuzeluleko, kepha awukwazi ukuyihlanza ngokunembile njenge-flux noma i-tip tinner. Ngaphandle kwalokho, kukhona lelo thuba elincane kodwa elingangabazeki lokwephula kwakho ngengozi iphoyinti. Q: Ngikhohlwa ukuhlanza i-iron yami yensimbi ngemuva kokuyisebenzisa. Ngingayihlanza kanjani ngempumelelo engaphezulu? I-Ans: Ayikho enye indlela yokuhlanza i-iron soldering ngemuva kokuyisebenzisa njalo. Sincoma ukubhala phansi isikhumbuzi sokuhlanza i-ayoni kunothi okunamathelayo bese usibeka eduze nendawo yakho yokusebenza. Ngaphandle kwalokho, ukulandela umhlahlandlela wethu kuzokusiza ukuqeda ukungcola noma ukugqwala okunzima kunakho konke. Q: Kuphephile ukuhlanza ithiphu lensimbi yami lapho kushisa? I-Ans: Ukuze uhlanze ukugqwala okuvela ku-iron tip yakho, unayo kwadingeka asebenzise i-flux noma ithiphu tinner. Ukuze wenze kanjalo, udinga qhubeka nokufudumeza insimbi futhi silandele inqubo esiyiphakamisile. Ukuze uthole ukungcola okungekho oksijeni, pholisa ithiphu lensimbi kuqala ukuze ukhuhle futhi usule ukungcola nemfucumfucu ethiphu.Isiphetho

Ithiphu ithatha isinqumo sokuthi ikhwalithi ye-solder- pro guys bayayazi. Ngaphandle kokuhlanzeka, i-solder izomane iwe ithiphu lensimbi. Kuzokwenza kube nzima kuwe ukwenza umsebenzi wakho we-soldering uma lokho kwenzeka. Njengoba siphakamisile phambilini, indlela engcono yokuhlanza i-ironing yakho ukuyihlanza njalo emva kokusebenzisa. Ngokwengeziwe, ungalandela indlela yokwenza i-tinning ukunciphisa ijubane le-oxidation. Kepha uma kungenzeka ukuthi usesimweni lapho ubungeke ukwazi ukuhlanza i-ayoni njalo futhi manje unensimbi enhle kabi ongayihlanza, umhlahlandlela wethu kusamele kube yipharagon.Ngingu-Joost Nusselder, umsunguli we-Tools Doctor, umakethi wokuqukethwe, kanye nobaba. Ngiyakuthanda ukuzama okokusebenza okusha, futhi kanye nethimba lami ngidale izindatshana zebhulogi ezijulile kusukela ngo-2016 ukuze ngisize abafundi abathembekile ngamathuluzi namathiphu okwenza.