Ngiyakuthanda ukudala okuqukethwe kwamahhala okugcwele izeluleko zabafundi bami, wena. Angilwamukeli uxhaso olukhokhelwayo, umbono wami owami, kepha uma uthola izincomo zami zilusizo futhi ugcina uthenga okuthile okuthandayo ngesinye sezixhumanisi zami, bengingathola ikhomishini ngaphandle kwezindleko ezengeziwe kuwe. Funda kabanzi

Impikiswano endala, angicabangi ukuthi lokhu okuthunyelwe kuzoba ukuphela kwayo. Kepha ngiqinisekile ukuthi ungaqiniseka ngokuthi yini edingayo uma kufikwa ekunqumeni phakathi kwalokhu okubili. Yebo, ezimbili zazo zibukeka zifana, kepha azifani neze.

Kulokhu okuthunyelwe sizomboza:

- Ingabe Ukugcotshwa Kungangena Esikhundleni Sokushisela?

- Ukushisela vs ukugoqa

- Kuyini ukuSoldering okuSoft?

- Ingabe ukugoqa kuhle njengokushisela?

- Iqine Kangakanani I-Solder Joint?

- Ingabe ama-solder Joints Ahluleka?

- Ngabe iBrazing Inamandla kuneWelding?

- Ukushisela Vs Brazing

- Ukuqinisa nge-Brazing Vs

- Imibuzo Evame Ukubuzwa

- Isiphetho

Ingabe Ukugcotshwa Kungangena Esikhundleni Sokushisela?

Yebo, ungenza ukunamathisela ngomthofu esikhundleni sokushisela kwesinye isikhathi. Ngaphandle kwalokho, i-soldering iyona kuphela inketho yamacala lapho izinsimbi ezimbili zingenakushiswa. I-Soldering ne-welding, le misebenzi emibili ifana ncamashi, kepha inqubo yabo namasu amancane ahlukile. Noma kunjalo, amalunga ashiselwe abhekwa njengamandla. Izinto ezingekho ayoni ezifana nethusi nethusi zingcono ukugogeka kune-weld. Kwezinye izimo, uma kungokwesakhiwo, kuphakanyiswa ukuthi ku-weld kune-solder. Uma kungeyona eyokwakha, ungafeketha esikhundleni sokushisela. Kepha ukujoyina kungenzeka kungafani.Ukushisela vs ukugoqa

Njengamagama amaningi eshidi lensimbi, i-soldering ne-welding zisetshenziswa ziyahambisana. Womabili la magama athathwa njengezindlela zokuhlanganisa izinsimbi. Kepha izinyathelo namasu kuyaphikisana. Ngokwazi kahle la magama amabili, uzothola umbono ocacile wokuthi iyiphi indlela elungele izidingo zakho.

Izinhlobo Zokushisela

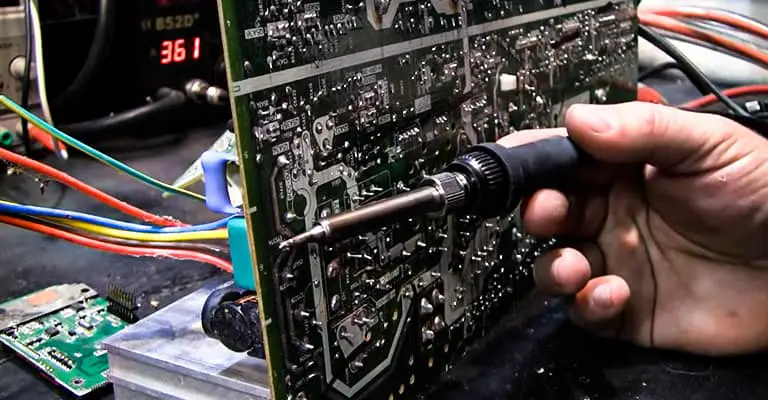

Ukushisela kuyinqubo yokubaza izinto evivinywa isikhathi, ikakhulukazi izinsimbi lapho izinga lokushisa eliphakeme lisetshenziselwa ukuncibilikisa insimbi eyisisekelo nokuxuba izingxenye. Inqubo isetshenziselwa ukwenza ukuhlangana phakathi kwezinsimbi ezimbili. Kepha esikhundleni sokushisa, ingcindezi ephezulu nayo ingasetshenziswa. Kunezinhlobo ezahlukene zokushisela. Uhlu lunikezwe ngezansi. I-MIG Welding Ukushisela kwe-MIG kwaziwa nangokuthi yi-Gas Metal Arc Welding. Luhlobo oludumile nolulula kakhulu futhi oluphakanyiswe kakhulu kubaqalayo. Lokhu kufakwa kuhlanganisa izinhlobo ezimbili. Uhlobo lokuqala lusebenzisa ucingo oluvulekile noma olungenalutho kanti olamuva lusetshenziswa umnyombo wokuhamba. Ware wire Welding is used to join different different thin met together. Ngakolunye uhlangothi, i-MIG flux core welding isetshenziselwa ukusetshenziswa kwangaphandle njengoba ingadingi noma iyiphi imitha yokugeleza nokunikezwa kwegesi. Uma uwumshiseli wokuzilibazisa noma umdlandla we-DIY, le nqubo yokushisela kungcono ukuyilanda. Uma kunjalo, yazi ukuthi kukhona impintshisi ezikhethekile zokushisela iMIG. I-TIG Welding Ukushisela kwe-TIG kwaziwa ngokuthi yi-Gas Tungsten Arc welding. Iwuhlobo oluthandwa kakhulu futhi oluguquguqukayo lwe-welding. Kodwa lokhu kushisela kungokwezinga lochwepheshe futhi kunzima ukukusebenzisa. Kufanele usebenzise izandla zakho zombili ngobuchule ukuze wenze i-TIG yokushisela kahle. Esinye sezandla zakho sidinga ukondla induku noma insimbi ofuna ukuyishisela kuyilapho esinye isandla sidinga ukubamba a Ithoshi ye-TIG. Ithoshi likhiqiza ukushisa kanye ne-arch ukushisela izinsimbi eziningi zendabuko ezihlanganisa i-aluminium, insimbi, ama-nickel alloys, ithusi, i-cobalt, ne-titanium. Ukunamathela Kwentambo Ukushisela induku kuthathwa njenge-Shielded Metal Arc Welding. Kulolu hlobo lwenqubo, i-welding yenziwa ngendlela yakudala. Kulula kune-TIG welding kepha kunzima kune-MIG welding. Ngokushisela induku, uzodinga induku yokushisela i-electrode. Ukushisela i-Plasma Arc Ukushisela kwePlasma Arc ubuchwepheshe obucophelelayo nobesimanjemanje obusetshenziswa kakhulu ekusetshenzisweni kwe-aerospace lapho ubukhulu bensimbi bungamayintshi angama-0.015 afana nensimbi yenjini noma uphawu lomoya. Inqubo yalokhu kufakwa kufana kakhulu ne-TIG welding. Ukushisa igesi I-Welding yegesi ayivamile ukusetshenziswa manje-izinsuku. I-TIG welding ithathe indawo yayo ikakhulu. Kulolu hlobo lokushisela, i-oxygen ne-acetylene kuyasetshenziswa futhi kuyaphatheka kakhulu. Isetshenziselwa ukushisela izingcezu zemoto emuva. I-Electron Beam ne-Laser Welding Luhlobo lokushisela olubiza kakhulu. Kodwa umphumela wale welding nawo uza ngokunembile kakhulu. Uhlobo lubhekwa njengendlela ephezulu yokushisela amandla.Izinhlobo Zokunamathisela ngomthofu

I-Solder inqubo yokuhlanganisa izinsimbi ezimbili noma ngaphezulu ngaphandle kokuncibilikisa insimbi eyisisekelo. Umsebenzi wenziwa ngokubeka i-alloy ehlukile ebizwa ngokuthi i-solder phakathi kwezinsimbi ezimbili bese leyo solder iyancibilika ukuyijoyina. Kunezinhlobo ezahlukahlukene ze-soldering ezifana ne-soldering ethambile, i-soldering enzima, ne-brazing. Ukunamathisela kanzima Inqubo yokufaka kanzima inzima kunaleyo ethambile. Kepha isibopho esidalwe yile nqubo siqine kakhulu. Ukushisa okuphezulu kusetshenziselwa ukuncibilikisa i-solder yale soldering. Imvamisa i-solder esetshenziswa kule nqubo yethusi noma isiliva futhi ukuyincibilikisa i-blowtorch iyadingeka. Yize iphuzu lokuncibilika lesiliva liphansi kakhulu kunethusi, liyabiza. I-soldering enzima yaziwa nangokuthi i-soldering yesiliva uma isetshenziswa nesiliva. Ukujoyina izinsimbi ezinjengethusi, ithusi, noma isiliva, kusetshenziselwa ukugoqa isiliva. I-Brazing I-Brazing nayo ibhekwa njengohlobo lwe-solder. Ifaka into ye-solder enendawo yokuncibilika ephezulu kakhulu kunaleyo esetshenziselwa ukunamathisela kanzima futhi okuthambile. Kepha ngokuqhathanisa, icishe ifane nokunamathisela ngomlilo kanzima. Izinsimbi eziyisisekelo ziyafudunyezwa futhi kulelo phuzu elifudumele, i-solder ebizwa ngokuthi i-brazing filler material ifakwa phakathi. I-solder iyancibilika ngokushesha ngemuva kokuyibeka. Kodwa-ke, kukhona umehluko othile phakathi kokunamathisela okujwayelekile nokubopha.Izinto Okufanele Uzicabangele

Ukunamathisela ngokuvamile kudinga ukushisa okuphansi njengoba insimbi yesisekelo ingancibiliki ngakho-ke iphuzu lokuncibilika kwe-solder kufanele libe ngaphansi kunensimbi eyisisekelo. Kepha i isibopho esenziwe nge-soldering ayiqinile njengokushisela njengoba ekushiseni akukho nsimbi eyengeziwe esetshenziswayo phakathi. Izinsimbi eziyisisekelo ziyancibilika futhi zihlanganiswe ndawonye ezinokwethenjelwa ngokwengeziwe. Ukushisela kungcono ezinsimbi ezinamaphuzu aphezulu okuncibilika. Ngokujoyina izinsimbi ezijiyile, i-welding ihamba phambili. Uma udinga ukuhlanganisa ngokuphelele izingcezu ezimbili zensimbi kuze kube ngaphesheya kunokuba kube ngesikhathi esisodwa, i-welding ngeke ibe yindlela enhle. Okwezinsimbi ezizacile futhi uma ufuna ukuphela okungenamthungo, i-soldering izoba ngcono.

Kuyini ukuSoldering okuSoft?

Inqubo yokufaka uthambile iyathandwa ezimbonini ze-elekthronikhi kanye namapayipi. Le ndlela isetshenziselwa ukwakha isibopho phakathi kwezakhi zikagesi kusekethe. Kule nqubo, i-solder yenziwa ngothini, umthofu nezinye izinhlobo zensimbi. Ukuqinisekisa ukulingana okulingene, wena ingasebenzisa into ene-asidi ebizwa nge-flux. Ku-soldering ethambile, kusetshenziswa i-soldering kagesi noma yensimbi esebenzisa igesi. Isibopho esidalwe yile soldering sibuthakathaka kakhulu kune-solder enzima. Kepha ngenxa yobulula bayo, le solder ivamile kubaqalayo.Ingabe ukugoqa kuhle njengokushisela?

Njengoba kushiwo ngaphambili, i-soldering ayinamandla njengokushisela. kodwa kwezinye izinsimbi, i-soldering isebenza kahle njengokushisela. Ngisho nakwezinye izinsimbi, njengethusi, ithusi, isiliva soldering isebenza kangcono kune-welding. Okokusebenza kagesi, amapayipi nobucwebe, i-soldering yenza ukuxhumana okusheshayo nokucocekile.Iqine Kangakanani I-Solder Joint?

Uhlobo oluhlanganisiwe lwe-4-intshi L-joint ngokuvamile luza nesilinganiso sengcindezi esingu-440 psi. i-solder yesiliva yamazinga okushisa aphansi inamandla aqinile we-10,000 psi. Kepha abathengisi besiliva bangaba namandla aqine ngaphezu kwe-60,000 psi okunzima kakhulu ukuthola.Ingabe ama-solder Joints Ahluleka?

Yebo, ukujoyina kwe-solder kwehlisa isikhathi futhi kungahluleka. Ukulayisha ngokweqile, kubangele ukwephulwa okuqinile, ukulayishwa okuhlala isikhathi eside nokulayishwa okujikelezayo kubangela ukuthi i-soldering yehluleke. Ukwehluleka kuvame ukwaziwa ngokuthi ukungena futhi kubangelwa amazinga okushisa aphezulu. Kepha ngenxa yalezi zizathu ezingenhla, kungenzeka futhi ekamelweni lokushisa.Ngabe iBrazing Inamandla kuneWelding?

Amalunga afakwe ubhedu angaqina kunokuba izinsimbi zingamalunga. Kepha azikwazi ukuqina kunamalunga ashiselwe. Okwe-welding base materials kuhlanganisiwe futhi izinto ezisisekelo zinamandla kunezinto zokugcwalisa. Izinto zokugcwalisa zinamaphuzu ancibilika aphansi. Ngakho-ke izinga lokushisa elidingekayo liphansi, kepha ngamandla, awafani.Ukushisela Vs Brazing

Ukushisela kujoyina izinsimbi ngokuxuba izinsimbi eziyisisekelo kanti, ukubhinca kujoyina insimbi ngokuncibilikisa okokugcwalisa. Izinto zokugcwalisa ezisetshenzisiwe zinamandla, kepha izinga lokushisa elidingekayo ekuboshweni liphansi kakhulu kunelezinsimbi. Ngakho-ke, ukubhinca kudla amandla amancane kunokushisela. Kepha kwezinye izinsimbi ezincanyana, ukubhincisa kungaba yindlela engcono.Ukuqinisa nge-Brazing Vs

Umehluko phakathi kwabo izinga lokushisa. Imvamisa, ku-soldering, okokugcwalisa kunendawo yokuncibilika engaphansi kuka-450C. Kepha ekubhangiseni, izinto ezisetshenzisiwe zinendawo yokuncibilika ngaphezulu kwe-450C. I-Brazing inomthelela omncane ezinsimbi kune-soldering. Ijoyinti elenziwe ngokufaka i-soldering alinamandla kangako kunalelo lokubopha.Imibuzo Evame Ukubuzwa

Q: Iyiphi insimbi engathengiswa? I-Ans: Ngokuvamile, zonke izinsimbi zingathengiswa. Kepha okunye kunzima kakhulu uku-solder, ngakho-ke kungcono ukugwema ukuwafaka njengensimbi engagqwali, i-aluminium, ithusi, njll. i-soldering aluminium isebenzisa i-soldering iron kudinga ukunakekelwa okukhethekile. Q: . Ingabe ikhona ingcina esebenza njengesosha? I-Ans: Yebo, iMesoGlue iyinhlaka yensimbi engasetshenziswa esikhundleni se-solder. Lo mkhiqizo usebenza ekamelweni lokushisa nasensikeni yensimbi ekwazi ukunamathisela izingcezu zensimbi kanye nokuzijimela kokuzilawula ngokulawulwa kukagesi. Q: Ngabe ngiyakudinga ukusebenzisa i-flux kuya ku-solder? I-Ans: Yebo wena udinga ukusebenzisa i-flux uma ingengezwe ku-solder. Ngokuvamile, iningi lamasosha asetshenziselwa ukusetshenziswa kwe-electronics anomgogodla wangaphakathi wokuguquguquka, uma kunjalo, awudingi eyodwa.Isiphetho

Ukuba yisisebenzi sensimbi noma i-hobbyist, kufanele wazi ngokushisela nokufaka izinsimbi. Uma ubathatha kalula, ungahle ungatholi imiphumela obuyilindele. Yize zifana impela ngaphandle, ezinye izici ezinkulu zibenze izindlela ezimbili eziphambili zokujoyina izinsimbi. Le ndatshana igxile emininingwaneni enembile ye-welding, i-soldering, ne-brazing nayo. Sethemba ukuthi kuzosusa konke ukudideka kwimigomo, umehluko wabo, ukufana, nezinkambu zokusebenza.Ngingu-Joost Nusselder, umsunguli we-Tools Doctor, umakethi wokuqukethwe, kanye nobaba. Ngiyakuthanda ukuzama okokusebenza okusha, futhi kanye nethimba lami ngidale izindatshana zebhulogi ezijulile kusukela ngo-2016 ukuze ngisize abafundi abathembekile ngamathuluzi namathiphu okwenza.