Kungenzeka ukuthi uke wacabanga ukuthola ipeni lokubasa izinkuni. Ngakolunye uhlangothi, ucabanga ukusebenzisa futhi i-soldering iron osewunakho.

Kukhona kokubili ukufana nomehluko phakathi kwamapeni abizayo okubasa izinkuni alenga ekhabetheni lesuphamakethe kanye nensimbi eshibhile ebekwe ekhoneni lendlu yakho.

Kodwa ingabe lezi kungaba ezinye izindlela zomunye nomunye? Ake sikuhlole.

Kulokhu okuthunyelwe sizomboza:

Yini eyenza umshini wokushisa izinkuni uhluke ensimbi ewuketshezi?

Yize le mikhiqizo ibonakala ifana ngaphandle, kunezinto eziningi eziyenza yehluke.

Nansi umehluko omkhulu.

Izicelo

Soldering iron kanye okhipha izinkuni amapeni anezinhloso ezahlukene. I-soldering iron ivame ukusetshenziselwa izintambo zokuhlanganisa, izingxenye zikagesi, namajoyinti.

Ipeni lokushisa izinkuni lisetshenziselwa kuphela i-pyrography, uhlobo lobuciko noma inqubo yokudweba izinkuni noma isikhumba ngokushisa umklamo endaweni.

Izinhlobonhlobo zamathiphu

Ngokungafani nezinsimbi ze-soldering, izibaya ezishisa izinkuni zinamathiphu ahlukahlukene aqondile, izindwani, namanye amathuluzi wemisebenzi yokubhala eningiliziwe nenembile.

Ukulungiswa kokushisa

Amapeni abasa izinkuni afika nezilawuli zokushisa ezilungisekayo ezivumela umsebenzi we-pyrography oguquguqukayo, kuyilapho ama-ayina amaningi asoda angenaso lesi sici.

Izinga lokushisa elivuthayo

I-50/50 tin & lead solder iyancibilika cishe ku-180-220 C.

Izinkuni ziyasha ngezinga lokushisa eliphakeme kune-solder liyancibilika. Izibasi zezinkuni zingafinyelela amazinga okushisa angama-400-565 C.

Izinto zethiphu

Amathiphu amaningi amapeni okubasa izinkuni enziwe ngensimbi ne-nichrome. Izeluleko ze-iron soldering zenziwe nge-copper core ehlanganiswe nensimbi. I-Copper ingumqhubi wokushisa omuhle kakhulu, kanti i-iron plating isetshenziselwa ukuqina.

Amanani

Izinsimbi eziningi ezisodayo zifika ngenani elishibhile, kuyilapho amasethi epeni lokushisa izinkuni ebiza kakhulu kunezinsimbi zokusoda.

Ngingakwazi ukusebenzisa i-soldering iron ukuze ngibase izinkuni?

Ngakho umbuzo uthi: ungasebenzisa insimbi yokunamathisela ngomlilo ukushisa izinkuni? Yebo, kodwa i-soldering iron ayiyona inketho ekahle yokushiswa kwezinkuni, nakuba ungayisebenzisa weld plastic!

Kodwa-ke, ungazama ukusebenzisa i-soldering iron ngezinjongo zokuhlola nokuzilolonga. Uma ufuna ukukuthwebula, naka lezi ziphakamiso ukuze uthole imiphumela engcono.

Sebenzisa ucezu lokhuni olulahliwe

Awufuni ukumosha ucezu lokhuni oluphelele oluzosetshenziselwa i-pyrography. Thatha ucezu oluncane lokhuni olulahliwe bese uluzama.

Shisisa i-soldering iron ngendlela efanele

I-solder iyancibilika ekushiseni okuphansi kunokushiswa kwezinkuni. Shisisa i-ayini yakho yokudambisa imizuzu eyi-10 ukuze uqiniseke ukuthi ishisa ngokwanele ukuze wenze izimpawu zokusha ezibonakalayo.

Sebenzisa ithiphu elisha

I-soldering iron inamathiphu angashintshwa. Thola ithiphu elisha, elibukhali ukuze uthole ukulawula okubushelelezi nokuzinzile kwensimbi.

Dweba uhlaka ngepensela

Cabangela ukudweba imidwebo yesimo ofuna ukusidweba ngepensela kuqala.

Hlanza ithiphu ngokuphindaphindiwe

Hlanza i-iron soldering (okungukuthi isihloko sensimbi yokunamathisela) njalo, njengoba ukhuni olushile lunamathela ichopho futhi lwenza kube nzima ukuphinde lusetshenziswe.

Sebenzisa indwangu noma indwangu, kodwa qaphela ngoba ithiphu lishisa kakhulu futhi lingabangela ukulimala okubi kakhulu.

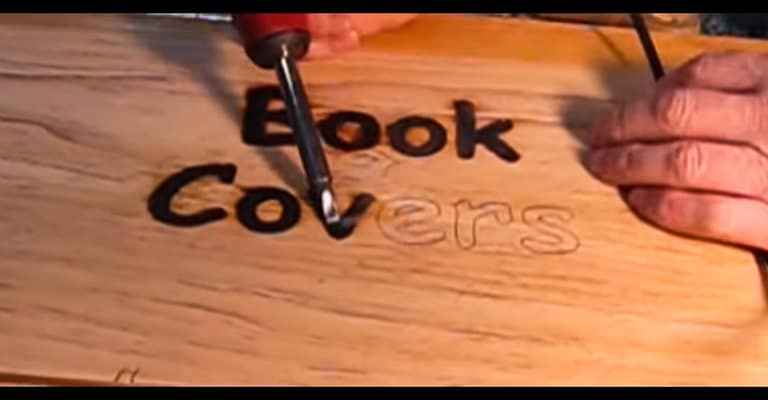

Uma ufuna ukwazi ngesishisi sokhuni uma uqhathaniswa nensimbi yokugoqa okhunini, bheka ividiyo ye-ADE-Woodcrafts yomsebenzisi we-YouTube:

Ngingakwazi ukusebenzisa ipeni lokubasa izinkuni emsebenzini wokusoda?

Uma ufuna ukujoyina amapayipi, ungasebenzisa ipeni lakho lokushisa izinkuni ngokwanele ukuhamba futhi solder. A i-soldering tip yensimbi isetshenziselwa ukuncibilikisa nokumanzisa i-solder.

I-ayina eshisa izinkuni ngokuvamile yenziwa ngensimbi futhi ayimanzisi i-solder. Ngakho-ke ngomsebenzi onemininingwane nonembile njengokuhlanganisa izingxenye ze-elekthronikhi, amapeni okushisa izinkuni ngeke abe usizo oluningi.

Izinto okufanele uzicabangele

Ngaphambi kokuba uqale ukushisa izinkuni zakho, qiniseka ukuthi akulona noma yiluphi uhlobo lwezinkuni ezilashwayo, ezinjengamakhemikhali, ama-varnished, apendiwe, avaliwe ngesiphetho, njll.

Ukushisa noma yiluphi uhlobo lwezinkuni ezilungisiwe, i-medium density fiberboard (MDF), amabhodi okwenziwa, kanye neplywood kukhipha ubuthi emoyeni. Lokhu kuyingozi kakhulu futhi kungase kubangele nomdlavuza nezinye izinkinga ezinkulu zezempilo.

Gqoka njalo imaski ngenkathi usebenza, njengokhuni Uthuli iyingozi futhi ingabangela izinkinga zokuphefumula namaphaphu.

Ungacabanga futhi ukusetha isistimu yokuqoqwa kothuli yekhwalithi yendawo ephephile yokusebenza.

Ingabe udinga amathuluzi womabili?

Izinhlobo ezahlukene zezinkuni zinezindlela ezihlukene zokusha ngokuya ngomswakama wazo, ukuminyana, nezinye izici.

Inani lokushisa ozolidinga, ingcindezi yethiphu ebusweni, nokuthi kuthatha isikhathi esingakanani ukwenza uphawu lokusha okhunini lakho nakho kuzohluka.

Ngakho-ke yenza ucwaningo oluncane mayelana nezinto ozozisebenzisa ngaphambi kokuqala umsebenzi.

Ngaphambi kokusebenzisa umshini wokushisa izinkuni ngomsebenzi wokuhlanganisa noma ngokuphambene nalokho, khumbula ukuthi umphumela awusoze wafana. Ongakwenza ukuhlela umsebenzi wakho ngokufanele ukuze uthole umphumela ongcono kakhulu.

Ngingu-Joost Nusselder, umsunguli we-Tools Doctor, umakethi wokuqukethwe, kanye nobaba. Ngiyakuthanda ukuzama okokusebenza okusha, futhi kanye nethimba lami ngidale izindatshana zebhulogi ezijulile kusukela ngo-2016 ukuze ngisize abafundi abathembekile ngamathuluzi namathiphu okwenza.