Prototyping is a great idea to test your design before creating a production-ready model. 3D Printers and CNC Machining are both viable options, but each has distinct advantages and limitations based on various project parameters. So which is the better option? If you are in this conundrum, then this article is just what you need. We will dive deep into both technologies and discuss many key factors to help you decide what is best based on your project needs.

In this post we'll cover:

3D Printing vs. CNC Machining: What’s the Difference?

Before we jump into the specifics, getting a good grip on the basics is best. The primary difference between 3D printing and CNC Machining is how the final product is achieved.

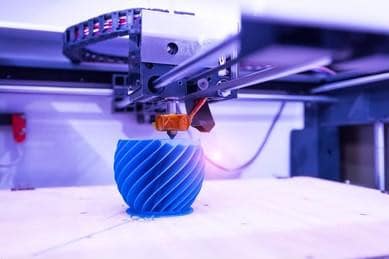

3D printing is an additive manufacturing process. This means that the end product is created by a 3D printer laying down successive layers of material on the work plate until the product’s final shape is achieved.

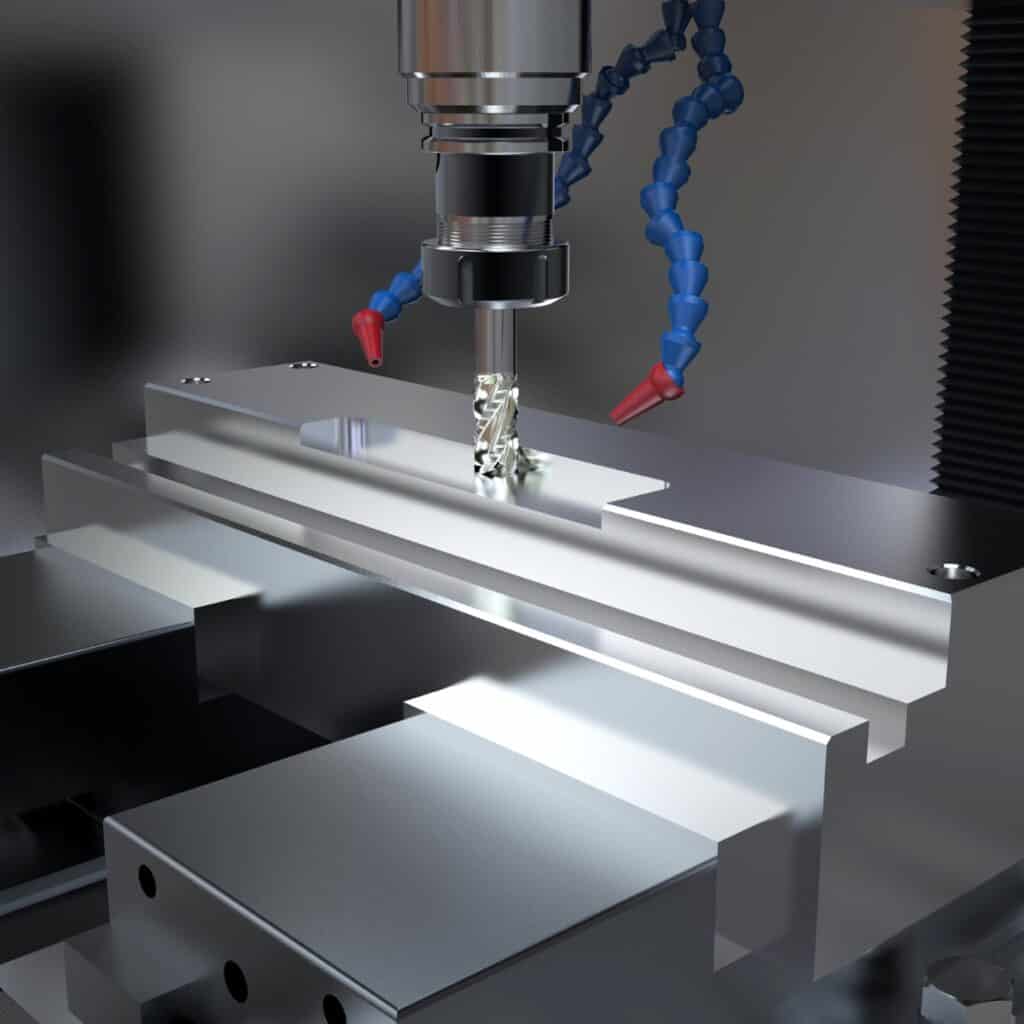

CNC Machining, on the other hand, is a subtractive manufacturing process. You start with a block of material called a blank and machine away or remove material to be left with the final product.

How to choose what’s best for your project needs?

Each of the two manufacturing techniques has distinct advantages in specific scenarios. Let’s look at each one individually.

1. The Material

When working with metals, CNC Machines have a clear advantage. Overall 3D printing is more focused on plastics. There are 3D printing technologies that can print metal, but from the perspective of prototyping, they can be very expensive as those industrial machines can cost upwards of $100,000.

Another downside with 3D printing metal is that your end product is not as structurally sound as the same part made by milling out a solid blank. You can improve the strength of a 3D-printed metal part by heat treating, which can cause the overall cost to skyrocket. Regarding superalloys and TPU, you have to go with 3D printing.

2. Production volumes and cost

If you are looking at quick one-off prototypes or low production volumes (low double digits), then 3D printing is cheaper. For higher production volumes (high double digits to a few hundred), CNC milling is the way to go.

Upfront costs of additive manufacturing are usually lower than subtractive manufacturing for one-off prototypes. That being said, all parts that do not require complex geometries can be manufactured more cost-effectively using CNC machining.

If you are looking at production volumes over 500 units, traditional forming technologies like inject molding are much more economical than additive and subtractive manufacturing techniques.

3. Design Complexity

Both technologies have their share of limitations, but in this context, 3D printing has a clear advantage. CNC machining cannot handle complex geometries due to factors such as tool access and clearances, tool holders, and mounting points. You also cannot machine square corners due to tool geometry. 3D printing allows a lot more flexibility when it comes to complex geometry.

Another aspect to consider is the size of the part you are prototyping. CNC machines are better suited to handle bigger parts. Not that there aren’t 3D printers out there that aren’t large enough, but from a prototyping perspective, the associated costs with a massive 3D printer make them unfeasible for the job.

4. Dimensional accuracy

For parts that require tight tolerances, CNC machining is a clear choice. CNC milling can achieve tolerance levels between ± 0.025 – 0.125 mm. At the same time, 3D printers generally have around ± 0.3 mm tolerance. Except for Direct Metal Laser Sintering (DMLS) printers that can achieve tolerance as low as ± 0.1 mm, this technology is way too expensive for prototyping.

5. Surface finish

CNC machining is a clear choice if a superior surface finish is a significant criterion. 3D printers can produce a pretty good fit and finish, but CNC Machining is the way to go if you require a superior surface finish to mate with other higher-precision parts.

A Simplified Guide to Help You Choose

Here is a quick guide to help you decide between 3D printing and CNC machining:

- If you are looking at rapid prototyping, which involves complex geometry for a one-off prototype or an extremely small production run, then 3D printing will be an ideal choice.

- If you are looking at a higher production run of a few hundred parts with relatively simple geometries, go with CNC machining.

- If we look at working with metals, then from a cost perspective, CNC machining has the advantage. This holds even for low quantities. However, geometry limitations still apply here.

- If repeatability, tight tolerance, and a perfect surface finish are highly prioritized, go with CNC machining.

The Final Word

3D printing is still a relatively new technology, and its battle for market dominance has only just begun. Yes, there are expensive and state-of-the-art 3D printing machines that have narrowed the gap to what CNC machining is capable of, but from the perspective of prototyping, they cannot be considered here. There are no one-size fits all solution. Choosing one over the other depends entirely on your prototyping project’s design specifications.

About the Author:

Peter Jacobs

Peter Jacobs is the Senior Director of Marketing at CNC Masters. He is actively involved in manufacturing processes and regularly contributes his insights to various blogs on CNC machining, 3D printing, rapid tooling, injection molding, metal casting, and manufacturing in general.

I'm Joost Nusselder, the founder of Tools Doctor, content marketer, and dad. I love trying out new equipment, and together with my team I've been creating in-depth blog articles since 2016 to help loyal readers with tools & crafting tips.