Fiberglass (or fibreglass) is a type of fiber reinforced plastic where the reinforcement fiber is specifically glass fiber. The glass fiber may be randomly arranged but is commonly woven into a mat.

The plastic matrix may be a thermosetting plastic- most often epoxy, polyester resin- or vinylester, or a thermoplastic. The glass fibers are made of various types of glass depending upon the fiberglass use.

In this post we'll cover:

- Breaking Down Fiberglass: The Ins and Outs of This Common Type of Fiber-Reinforced Plastic

- The Fascinating History of Fiberglass

- Creating Fiberglass Products: The Manufacturing Process

- The Versatility of Fiberglass Applications

- Carbon Fiber and Glass-Reinforced Plastic vs Fiberglass: The Battle of the Fibers

- Recycling Fiberglass: A Green Alternative for Tough Needs

- Conclusion

Breaking Down Fiberglass: The Ins and Outs of This Common Type of Fiber-Reinforced Plastic

Fiberglass, also known as fibreglass, is a type of fiber-reinforced plastic that uses glass fibers. These fibers can be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth.

What are the Different Forms of Fiberglass?

As mentioned earlier, fiberglass can be in the form of randomly arranged fibers, a chopped strand mat, or woven into glass cloth. Here’s a little more information on each:

- Randomly arranged fibers: These fibers are often used in insulation and other applications where a high degree of flexibility is needed.

- Chopped strand mat: This is a sheet of fiberglass that has been flattened and compressed. It’s often used in boat building and other applications where a smooth surface is desired.

- Woven glass cloth: This is a fabric made from fiberglass fibers that have been woven together. It’s often used in applications where a high degree of strength is needed.

What are Some Common Applications of Fiberglass?

Fiberglass is used in a wide variety of applications, including:

- Boat building

- Automobile parts

- Aerospace components

- Wind turbine blades

- Building insulation

- Swimming pools and hot tubs

- Surfboards and other water sports equipment

What’s the Difference Between Carbon Fiber and Fiberglass?

Carbon fiber and fiberglass are both types of fiber-reinforced plastic, but there are some key differences between the two:

- Carbon fiber is stronger and stiffer than fiberglass, but it’s also more expensive.

- Fiberglass is more flexible than carbon fiber, which makes it a better choice for applications where some degree of flexibility is needed.

How is Fiberglass Recycled?

Fiberglass can be recycled, but the process is more difficult than recycling other materials like aluminum or paper. Here are a few methods that are used:

- Grinding: Fiberglass can be ground up into small pieces and used as a filler material in other products.

- Pyrolysis: This involves heating the fiberglass to a high temperature in the absence of oxygen. The resulting gases can be used as fuel, and the remaining material can be used as a filler material (here’s how to use fillers).

- Mechanical recycling: This involves breaking down the fiberglass into its component parts and reusing them to make new products.

The Fascinating History of Fiberglass

• Fiberglass was discovered in the late 19th century by accident when a researcher at Corning Glass Works spilled molten glass onto a stove and observed that it formed thin fibers when it cooled.

- The researcher, Dale Kleist, developed a process to manufacture these fibers and the company marketed them as an alternative to asbestos.

Marketing of Fiberglass

• During World War II, fiberglass was used for military applications such as radomes and aircraft parts.

- After the war, fiberglass was marketed for a variety of uses including boat hulls, fishing rods, and automobile bodies.

Insulation

• Fiberglass insulation was developed in the 1930s and quickly became a popular choice for insulating homes and buildings.

- It is still widely used today and can be found in various parts of the building envelope, including walls, ceilings, and attics.

- Fiberglass insulation is effective at reducing heat loss and noise transmission.

Fiberglass is an ideal material for a wide range of applications, thanks to its lightweight, high strength, and excellent resistance to water and chemicals. Here are some of the most common uses of fiberglass forms:

- Construction: Fiberglass is commonly used in construction for its excellent insulation properties and ability to prevent water damage.

- Containers: Fiberglass containers are popular in the food industry, as they offer excellent protection and storage for sensitive food products.

- Boat Building: Fiberglass is a popular material for boat building, thanks to its lightweight and high strength.

- Covers: Fiberglass covers are commonly used in the construction industry to protect sensitive equipment from the elements.

- Molded Components: Fiberglass is an ideal material for producing molded components, thanks to its ability to take on different shapes and forms.

Creating Fiberglass Products: The Manufacturing Process

To create fiberglass, a combination of raw materials such as silica, sand, limestone, kaolin clay, and dolomite are melted in a furnace until they reach a melting point. The melted glass is then extruded through tiny brushings or spinnerets to produce tiny extrusions called filaments. These filaments are woven together to create a fabric-like material that can be molded into any desired shape.

Addition of Resins

To increase the performance and durability of fiberglass, additional materials such as resins are added during production. These resins are mixed with the woven filaments and molded into the desired shape. The use of resins allows for increased strength, flexibility, and resistance to weather and other external factors.

Advanced Manufacturing Techniques

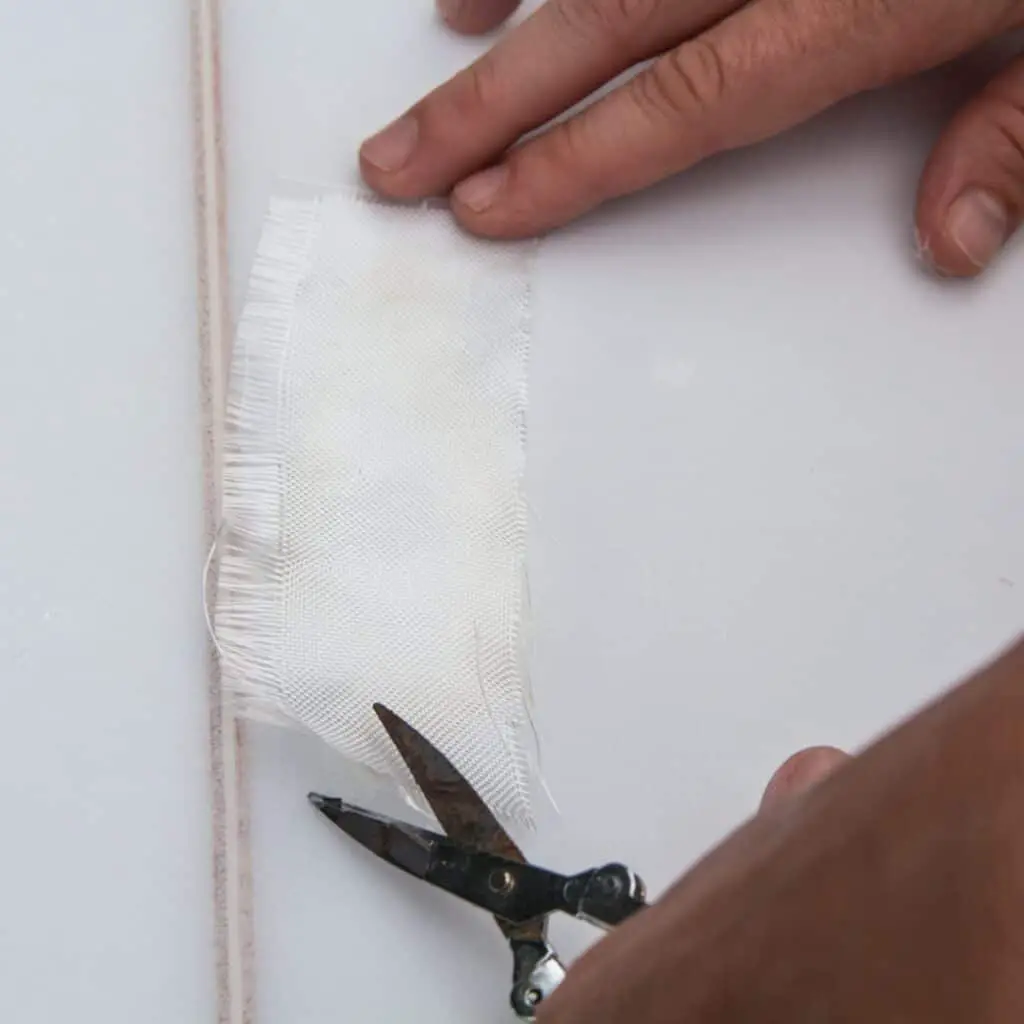

With advanced manufacturing techniques, fiberglass can be molded into massive shapes, making it ideal for building new products. The use of fiberglass mats allows for the creation of light and durable products that can suit a wide range of applications. The manufacturing process can be cut to suit the desired shape and size of the product, making it an ideal replacement for existing materials.

The Versatility of Fiberglass Applications

Fiberglass is a lightweight and durable material that has become increasingly popular in various industries due to its unique properties. It comprises of glass fibers that are combined with a polymer to create a strong and versatile material that can be utilized in a wide range of applications.

Carbon Fiber and Glass-Reinforced Plastic vs Fiberglass: The Battle of the Fibers

Let’s start with some definitions. Fiberglass is a composite material made of fine glass fibers and a polymer base, while carbon fiber is a composite material made of carbon fibers and a polymer base. Glass-reinforced plastic (GRP) or fiberglass-reinforced plastic (FRP) is a composite material made of a polymer matrix reinforced with glass fibers. Both carbon fiber and glass-reinforced plastic are forms of composites, which means they are made by combining two or more materials with different properties to create a new material with superior mechanical properties.

Strength and Weight Ratio

When it comes to strength, carbon fiber boasts a strength to weight ratio roughly twice that of fiberglass. Industrial carbon fiber is more than 20 percent stronger than the best fiberglass, making it the dominating material in industries where strength and weight are crucial factors. However, fiberglass is still a popular choice in applications where cost is a major concern.

Manufacturing and Reinforcement

The manufacturing process for carbon fiber involves melting and spinning carbon-rich materials into fibers, which are then combined with a liquid polymer to facilitate the manufacturing of composites. On the other hand, fiberglass is made by weaving or laying glass mats or fabrics into a mold and then adding a liquid polymer to harden the material. Both materials can be reinforced with additional fibers to increase their strength and durability.

Interchangeability and Properties

While carbon fiber and fiberglass are often used interchangeably, they have different mechanical properties. Carbon fiber is stiffer and stronger than fiberglass, but it is also more brittle and expensive. Fiberglass, on the other hand, is more flexible and less expensive than carbon fiber, but it is not as strong. Glass-reinforced plastic falls somewhere in between the two in terms of strength and cost.

Recycling Fiberglass: A Green Alternative for Tough Needs

Fiberglass is a tough and durable material that can resist heat, water, and chemicals. It’s a popular choice for insulation, boats, cars, and construction. However, when it comes to disposing of old fiberglass, it’s not that easy. Fiberglass is made of plastic and glass fibers, which are not biodegradable. If not handled properly, it can release toxins into the environment and harm wildlife and humans.

The Process of Recycling Fiberglass

Recycling fiberglass takes a special process called thermal recycling. The fiberglass is heated to a high temperature, which transforms the organic compounds in the plastic into gas. This gas is collected and refined to yield both gas and oil. The gas is similar to natural gas and can be used for fuel. The oil can be used as a substitute for crude oil in some products.

The Usable End Product

Recycled fiberglass can be used as an alternative to new fiberglass in many applications. It can be used to build boats, cars, and homes. It can also be used for insulation, sea walls, and other special needs. Recycled fiberglass is tough and durable, just like new fiberglass, but it’s also green and sustainable.

The Billion Pound Claim

According to the Fiberglass Recycling website, manufacturers in North American and Canadian transfer stations and recycling centers accept postconsumer fiberglass, including old boats, cars, and styrofoam. The website claims that they recycle over a billion pounds of fiberglass each year. This is a significant amount that helps reduce waste and protect the environment.

Conclusion

So, fiberglass is a material made of glass fibers, used for a variety of things. It’s strong, lightweight, and resistant to water, and it’s been around for a long time. I hope you now know a little more about it.

I'm Joost Nusselder, the founder of Tools Doctor, content marketer, and dad. I love trying out new equipment, and together with my team I've been creating in-depth blog articles since 2016 to help loyal readers with tools & crafting tips.