Soldering is the process of joining 2 metals with each other for a stronger and robust joint. This is done by using a filler metal.

This technique of connecting metals with one another is widely used in electronics. Plumbing and metalworks also have extensive use of this technique.

Depending on the case, different types of fluxes are used. Electronics soldering is a rather sensitive field where the flux used should have certain attributes, like non-conductivity.

In this article, I’ll tell you about the types of flux that are used in electronics soldering, and what you should consider before using one of them yourself.

In this post we'll cover:

Why is flux required in electronics soldering?s Flux Required in Electronics Soldering

While you try to fill the joining point of 2 metals with another metal (which is essentially soldering), dirt and debris on those metal surfaces hinder the creation of a good joint. You can remove and clean the non-oxidizing dirt from those surfaces easily, but you have to use flux when you’re trying to remove oxidation.

Oxidation: Is it a bad thing?

Oxidation is a natural thing. But that doesn’t mean it’s all good.

All metals react with the oxygen in the air and from complex chemical compounds on the metal surface that is hard to remove and makes it very difficult to solder. Oxidation is commonly called rust on iron.

Use of flux to remove oxidation

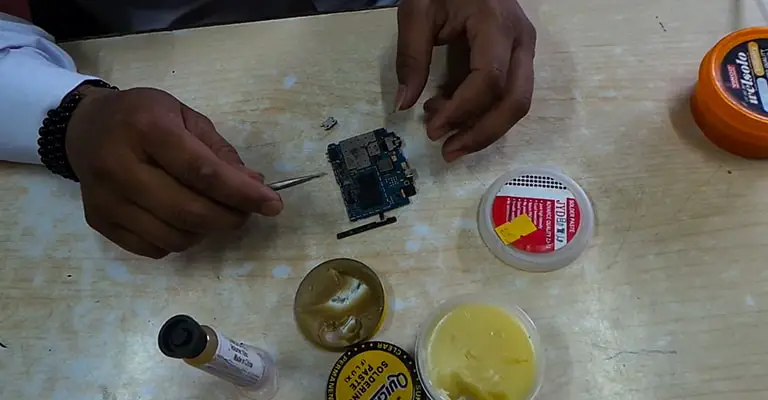

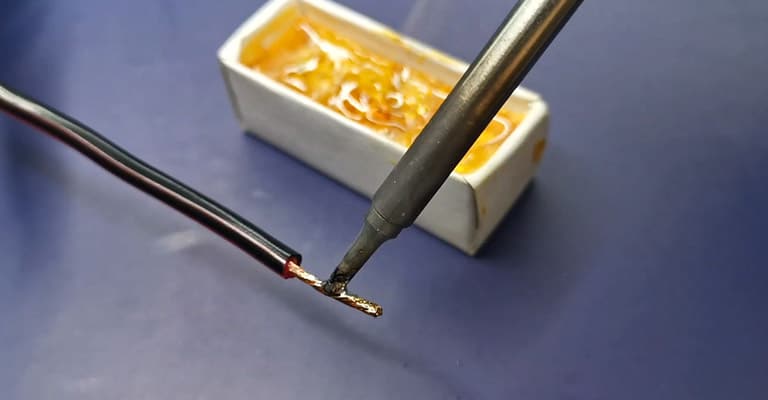

Flux is another chemical compound that reacts with oxidation, under high temperature, dissolving, and removing oxidation. You need to frequently use flux to clean oxidation from your soldering iron tip because higher temperatures accelerate it.

Keep this in mind if you’re intending to make your own soldering iron.

Different types of flux in electronic soldering

The flux that’s used on electric circuit boards isn’t the same type as those used on wires since they require different properties from flux.

Below, I’ll tell you about all the types of flux that are available on the market for electronics soldering.

Rosin flux

Beating all other fluxes in terms of age is rosin flux.

During the early days of production, rosin fluxes were created from pine sap. After the sap’s collected, it’s refined and purified into rosin flux.

However, nowadays, other different chemicals and fluxes are mixed with refined pine sap to produce rosin flux.

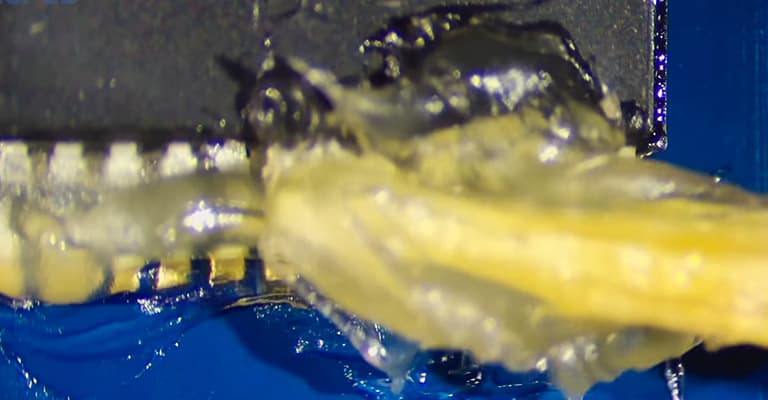

Rosin flux turns into liquid acid and flows easily when heated. But upon cooling, it becomes solid and inert.

It’s very effective in removing oxidation from metals. After using it on circuits, you can leave it in its solid, inert state. It won’t react with anything else unless it’s heated enough to turn into acid.

If you want to remove the residue after using rosin flux, you need to use alcohol, as it’s not water-soluble. That’s why you have to use alcohol instead of plain water.

But there’s no harm in leaving residue as it is, unless you wish to do a wise job of keeping your circuit board clean.

Organic acid flux

Organic acids like citric acid, lactic acid, and stearic acids are used to create this type of flux. The weak nature of these acids, combined with isopropyl alcohol and water, forms organic acid fluxes.

The biggest advantage of organic acid fluxes is that they’re completely water-soluble, unlike rosin flux.

In addition to that, as the acidic property of organic acid fluxes is higher than rosin fluxes, they’re stronger. As a result, they can clean oxides off of metal surfaces more quickly.

Couple this oxidation removing power with its soluble nature, and you have an easy-to-clean flux residue. No alcohol required!

Nevertheless, this cleaning benefit comes at a cost. You lose the non-conductivity property of the rosin flux residue since it’s electrically conductive and can affect the overall performance and operation of a circuit.

So make sure that you remove the flux residue after soldering.

No-clean flux

Just like the name suggests, you don’t need to clean the residue from this type of flux. It creates a significantly small amount compared to the other 2 fluxes.

No-clean flux is based on organic acids and some other chemicals. These often come in syringes for convenience.

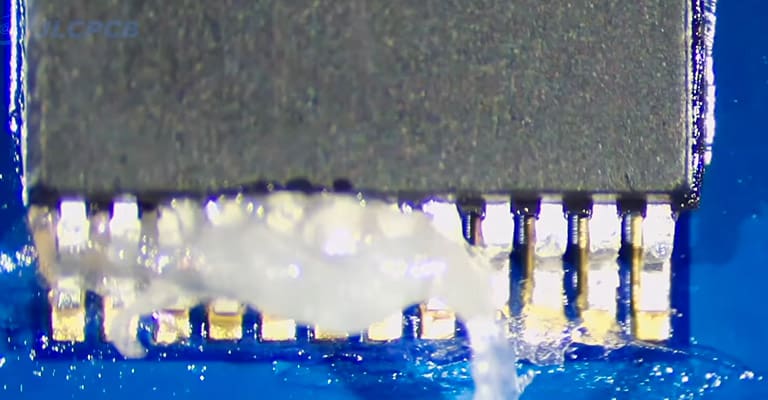

For circuits that use surface-mount technology, it’s better to use this type of flux.

Also, the ball grid array is a type of surface-mounted board that heavily benefits from no-clean fluxes. The small amount of residue it produces isn’t conductive or corrosive. You can use them on boards that are harder to access after installation.

However, some users find a surprisingly large amount of residue that’s hard to remove, apart from being conductive.

Be careful when using these fluxes on analog boards with high impedance. We recommend doing further inquiry before using the no-clean flux you’re planning to use.

Type of flux to avoid in electronics soldering: Inorganic acid flux

Inorganic acid fluxes are produced from a mixture of strong acids including (but not limited to) hydrochloric acid.

You must avoid inorganic flux on circuits or any other electronic parts, as both the flux and its residue can be corrosive. They’re meant for stronger metals, not electronic parts.

Check out YouTube user SDG Electronics’ video on the best flux for soldering:

Use the right type of flux for the job

As you could see, all types of flux have their advantages and disadvantages when it comes to using flux for soldering. You now have a range to choose from while doing your soldering work on electronics.

Nobody can declare any one of those fluxes as the best one out there, as different jobs will require different fluxes.

If you work on circuits that use surface-mount technology, your best bet would be the no-clean flux. But be careful about the extra residue thing.

And for other circuits, you can choose anything between organic acid flux and rosin flux. Both of them do an excellent job!

I'm Joost Nusselder, the founder of Tools Doctor, content marketer, and dad. I love trying out new equipment, and together with my team I've been creating in-depth blog articles since 2016 to help loyal readers with tools & crafting tips.