I love creating free content full of tips for my readers, you. I don't accept paid sponsorships, my opinion is my own, but if you find my recommendations helpful and you end up buying something you like through one of my links, I could earn a commission at no extra cost to you. Learn more

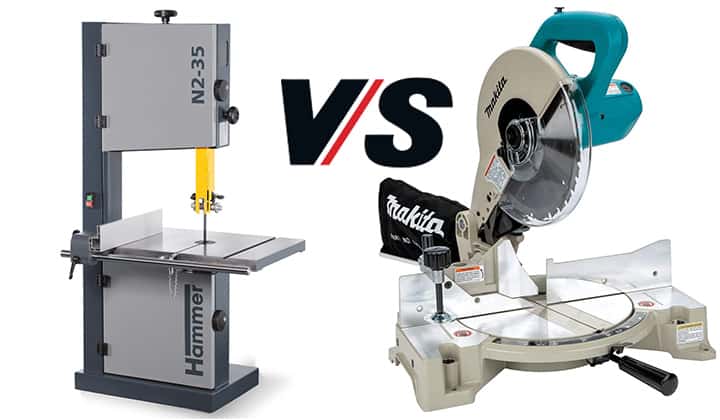

Among different power saws and cutting tools, bandsaws and chop saws are essential for woodworking, metalworking, and lumbering. Along with professional carpenters and metal workers, people also use them as a tool needed for various household tasks.

But if you need to choose between these two for your professional or personal work, which one would you prefer? band saw vs chop saw– which will be more beneficial to you?

In this post we'll cover:

What Is a Bandsaw?

A bandsaw is a cutting machine or electrical saw used for cutting, shaping, ripping, and resawing. With the right blade, it can cut various materials irrespective of their size and thickness. Almost every workshop needs a good quality bandsaw for perfect cuts and versatile uses, which might not be possible with other cutting tools. Apart from workshops and factories, they are also used in personal workspaces to cut small to medium workpieces. There are two corresponding wheels on two sides of a bandsaw. A vertical blade is mounted o a wheel as a band, and the whole setup of a bandsaw is mounted on a table stand. An electrical motor ensures a power supply to the bandsaw that runs the blade.What Is a Chop Saw?

You will find most of the power saws have straight or vertical blades attached to a moving point. But in the case of chop saws, things are a bit different. Chop saws have a large and round blade that is attached to a stationary holder, which acts as an arm. You can work with it by keeping a base underneath the edge to support the cutting material. Generally, you have to hold the arm and manage the workpiece with another hand. But nowadays, there is a range of chop saws which can be operated by your feet. They are more convenient as you can use both hands for adjusting the cutting material.Differences Between Bandsaws and Chop Saws

Though bandsaws and chop saws are both used for cutting various materials, there are a lot of differences between them that make each tool a unique one. The advantages and disadvantages of these two don’t make each other go downwards because of their specialties. Some noteworthy differences between a bandsaw and a chop saw are stated here.1. Functionality and Working Principle

When you turn on a bandsaw, the electric motor provides power to the blade, and it moves downwards to cut the target material. Before starting the cutting procedure, it is essential to adjust the necessary tension of the blade by attaching the blade guard properly because improper blade tension can make blades crackdown easily. Both hydraulics and continuous current supply can power chop saws through an electrical cord. When powered, the round blade spins at high speed and cuts the material. For cutting large and hard blocks by chop saws, hydraulics are better as they provide maximum power. But the corded ones are widely used because of their convenient usability.2. Blade Design

Band saws use narrow blades for cutting curves and wide blades for cutting straight lines. But in the case of quicker cuts, hook-tooth edges are better than regular blades. Besides, you can use skip-tooth blades if you are working on softer materials and want a flawless cut without ruining the shape.

3. Types

Generally, two types of bandsaws are seen widely: the vertical band saws and the horizontal band saws. The vertical saw is the regular one that works by a motor, and the blade runs down through the workpiece. But the horizontal saw is a bit different as the saw works in pivot style motion and operating principles. While in chop saws, you will find mainly four types: standard, compound, dual-compound and sliding compound. These four saws differ in functionality and working methods.4. Using Purposes

Bandsaws are versatile tools suitable for cutting wood, metal, plastic, lumber, and many other materials. You can have different types of cuts like straight, curved, angled, and circular, along with ripping lumber and resawing woodblocks. A bandsaw will give its best performance regardless of the thickness and dimensions of any workpiece. On the other hand, chop saws are great for cutting pipes and trimming lumber. If you want accurate cuts with the perfect angle, nothing can be better than this saw. They work fast and cut a considerable amount of material pieces in a short time, and this is why they are widely used in large-scale operations and tasks.Which One You Should Choose?

A bandsaw is more reliable if you want a power saw that can work well on almost every material and surface. As they are generally stationary tools, it is better to use them if you work in a workshop or factory. In case you want the highest accuracy in every cut, even for a hundred and thousand pieces of material blocks, chop saws are the best among all. Unlike a bandsaw, you can move them from one site to another, so they can be used as a portable cutting saw.Final Words

While choosing the best power saw, often people get confused between band saw vs chop saw. Here, we have covered up almost every difference between these two tools so that you can know the ultimate guide to select your preferred one. I hope this article helps!I'm Joost Nusselder, the founder of Tools Doctor, content marketer, and dad. I love trying out new equipment, and together with my team I've been creating in-depth blog articles since 2016 to help loyal readers with tools & crafting tips.