Decking doesn’t have to be stressful or painful, it should be fun and easy. The BW-2 BoWrench tool is the right tool for all your decking projects, especially if you love working with ease and comfort. The design of this tool is quite simple, which makes it perfect for professional deck builders and DIYers.

Perfect for decking a range of wooden materials like cedar, redwood and, more exotic rot-resistant woods that warp, especially woods that are sized 14ft to 16ft length. The BW-2 BoWrench Decking tool is quick and easy to use.

Boards could be pushed or pulled into alignment. The tool locks in place when placed perpendicularly, making it easier to drive nails and screws while holding the board still.

In this post we'll cover:

- Cepco Tool BW-2 BoWrench Decking Tool Review

- FAQ

- How can I make my deck boards tighter?

- How do you use a board bender deck tool?

- How do you align deck boards?

- How do you straighten treated lumber?

- How do I keep my wood deck from warping?

- Can I Unwarp wood?

- How do I keep my decking looking good?

- Do you screw decking at every joist?

- Should I put space between deck boards?

- How many screws should I put in decking?

- What can I use for deck board spacers?

- How do you attach a ledger board to concrete?

- How long should deck board screws be?

Cepco Tool BW-2 BoWrench Decking Tool Review

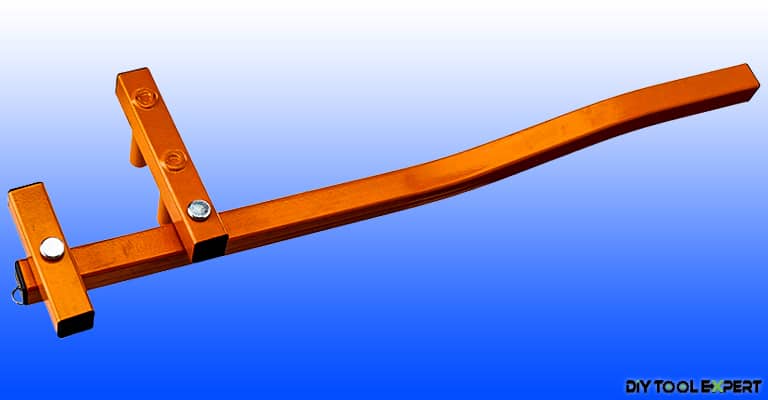

The BW-2 BoWrench decking tool comes with so many amazing features that get all your decking projects done in no time. With these features, you get to secure your wood connection and avoid toenailing as much as possible. Below are some of our the unique features that earned it a spot as one of our most preferred decking tools;

Durability

The durability of this tool is one of the many reasons why this tool is perfect for decking projects. You get to use this tool for longer periods without having to repair or even worse, purchase a new one. Its heavy-gauge steel construction is the reason behind the sturdiness of this decker.

Custom sized or Adjustable sized Grippers

The grippers of this tool are adjustable making it easier to work on joists and lumbers of different sizes. Getting rid of crowns that are impossible to pull with your hands is also possible by adjusting the size of the grippers to fit into the joists perfectly.

Cam lock

The cam locks in place for efficient one-man operation. You’d only need one hand for decking operations as the cam locks in place, giving you the opportunity to screw your boards.

Lightweight Features

Weighing about 4.6 pounds, the BW-2 BoWrench is easy to lift and operate. Working with just one hand is also made easier all thanks to its lightweight, bringing this tool to wherever your decking project is, wouldn’t stress you.

Size

With a handle length of 24 inches, closing up gaps of up to 2-inches is easy and possible. With its ability to close a considerably large number of gaps between boards, you get to save materials and money too.

FAQ

Here are some frequently asked questions and their answers.

How can I make my deck boards tighter?

Straighten crooked boards with a chisel, clamp or nail

Start nails into the deck board. Drive a 3/4-in. wood chisel into the joist and tight to the edge of the deck board with the bevel facing you. Pull back on the chisel until the deck board is tight to your spacer and drive the nails.

How do you use a board bender deck tool?

How do you align deck boards?

You can’t keep your deck boards straight if the joists on which you’re installing them aren’t flat. Make sure your joists are level to avoid your boards being wavy. To do this, stretch a chalk line over your joists to find any joists that are too high. Then, plane these high joists down using a power hand planer.

How do you straighten treated lumber?

To straighten warped wood, I soak in water. Or if you can’t submerse them put a wet cloth on the inside of the warp curve, and soak until straight. Once straight, switch the water formula for an Elmer’s white glue or the wood glue with water.

How do I keep my wood deck from warping?

Generally, six screws placed the length of your board will keep the board flat and secure. Use two screws at either end of the board and two more towards the outside of the board at every joist. This will keep the boards in place, giving them no room to move or warp.

Can I Unwarp wood?

It is always not possible to unwarp the wood into its original shape. But you can get close to fix the problem, only when you know how to use heat properly. … You need to continue applying heat until it gets very hot. After that slowly bend the warped board and wait for it to cool down.

How do I keep my decking looking good?

Firstly – Keep your decking clear.

Make sure you sweep leaves away regularly and in Spring and Autumn clean between the boards with a filling or putty knife to remove any build up that might cause the boards to decay. Make sure you wash away any bird droppings quickly as these can cause staining to your decking.

Do you screw decking at every joist?

Start the installation by securing each board with a few screws to keep them in place. … Once all of the decking is in place, snap a chalk line so that the screws can be installed in straight rows over the underlying framing. Each board should recieve 2 screws per joist, spaced about an inch from each edge.

Should I put space between deck boards?

The goal is to have about an 1/8-inch gap (the diameter of an 8d nail) between boards after the decking has dried to its equilibrium moisture content. If the decking is installed wet, as is often the case for pressure treated material, it is best to install the boards tight, letting gaps form as the wood dries.

How many screws should I put in decking?

Each deck board should be fastened with two screws at each point where the board crosses a joist to ensure the stability and durability of your deck’s surface. Boards should be fastened to rim joists with three screws.

What can I use for deck board spacers?

Sixteen-penny nails work great as spacers when you’re installing deck boards, but they often fall through the cracks. Keep the nails in place by pounding them through plastic jar covers. They’re easier to move and will stay up on the deck instead of falling on the ground.

How do you attach a ledger board to concrete?

Use a wood bit to drill ½” pilot holes through the ledger board. Next, use a concrete bit to drill into the concrete wall. Install two bolts at the end of each ledger board. Hammer the sleeve anchor through the ledger board into the concrete wall.

How long should deck board screws be?

2 1/2 inches

Most decking screws are 8-gauge and, while 2 1/2 inches is the minimum length needed to hold decking boards to the joists, 3-inch screws are commonly used to provide extra holding power against the upward pressure of shrinking or warping boards.

Conclusion

The Cepco BW-2 BoWrench decking tool is a hard worker. If you do a lot of decking, building gazebos and, porches, the BW-2 BoWrench is just the right tool for you. Using this tool would help you get the job done efficiently, leaving you satisfied. It also comes in a bright red color, adding to its aesthetics.

A lot of customers have found this tool really useful; you’d find out it’s of great help too. You’d notice faster progress in your decking projects while using this tool with absolutely no regrets at all.

I'm Joost Nusselder, the founder of Tools Doctor, content marketer, and dad. I love trying out new equipment, and together with my team I've been creating in-depth blog articles since 2016 to help loyal readers with tools & crafting tips.