You might have thought of getting a wood-burning pen. On the other hand, you’re also thinking of using the soldering iron that you already have.

There are both similarities and differences between the expensive wood-burning pens hanging in the supermarket closet and the cheap soldering iron lying in the corner of your house.

But can these be each other’s alternatives? Let’s check it out.

In this post we'll cover:

What makes a wood burner different from a soldering iron?

Even though these products appear to be the same on the surface, there are quite a lot of things that make them different.

Here are the main differences.

Applications

Soldering iron and wood burner pens have different purposes. A soldering iron is generally used for soldering wires, electronics parts, and joints.

A wood-burning pen is solely used for pyrography, a type of art or technique of painting wood or leather by burning a design on the surface.

Varieties of tips

Unlike soldering irons, wood-burning pens have tons of different pointed tips, blades, and other tools for detailed and precise pyrography works.

Heat adjustments

Wood-burning pens come with adjustable temperature regulators that allow versatile pyrography work, while most soldering irons don’t have this feature.

Burning temperature

50/50 tin & lead solder melts around 180-220 C.

Wood burns at a higher temperature than solder melts. Wood burners can reach temperatures of 400-565 C.

Tip material

Most tips for wood-burning pens are made of iron and nichrome. Soldering iron tips are made of copper core plated with iron. Copper is an excellent heat conductor, and the iron plating is used for durability.

Price range

Most soldering irons come in a cheap price range, whereas wood burner pen sets are more expensive than soldering irons.

Can I use a soldering iron for wood burning?

So the question is this: can you use a soldering iron to burn wood? Yes, but a soldering iron isn’t an ideal option for wood burning, though you can use it to weld plastic!

However, you can try using a soldering iron for experimentation and practice purposes. If you want to give it a shot, consider these suggestions to get better results.

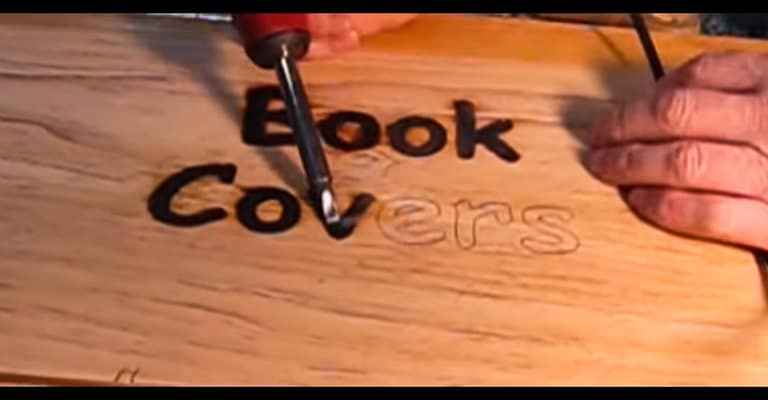

Use a piece of scrap wood

You don’t want to mess up the perfect piece of wood that’s going to be used for pyrography. Take a small piece of scrap wood and try it out.

Heat the soldering iron properly

Solder melts at a lower temperature than wood burns. Heat your soldering iron for 10 minutes to make sure it’s heated enough to make visible burn marks.

Use a new tip

The soldering iron has replaceable tips. Get a new, sharp tip to get smooth and stable control of the iron.

Draw outlines with a pencil

Consider drawing outlines of the shape you want to draw with a pencil first.

Clean the tip repeatedly

Clean the soldering iron (i.e. the tip of the soldering iron) frequently, as burnt wood sticks to the tip and makes it difficult for further use.

Use a piece of cloth or a rag, but be cautious because the tip is very hot and may cause severe burn injuries.

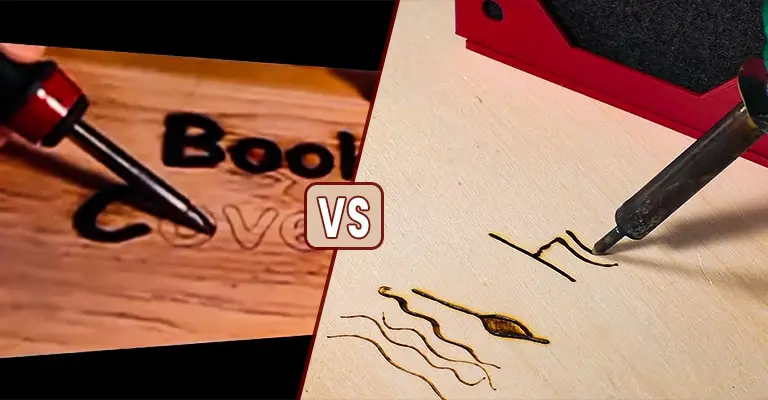

If you’re curious about a wood burner vs soldering iron on wood, then check out YouTube user ADE-Woodcrafts’ video:

Can I use a wood-burning pen for soldering work?

If you want to join pipelines, you may use your wood-burning pen with enough flux and solder. A soldering iron tip is used to melt and wet the solder.

A wood-burning iron is very often made of iron and that doesn’t wet the solder. So for detailed and precise work like assembling electronic components, wood burner pens won’t be much help.

Things to consider

Before you start burning your wood, make sure that it isn’t any type of treated wood, such as chemically treated, varnished, painted, sealed with a finish, etc.

Burning any kind of prepared wood, medium density fiberboard (MDF), synthetic boards, and plywood releases toxins into the air. This is very hazardous and may even cause cancer and other major health issues.

Always wear a mask while working, as wood dust is harmful and can cause respiratory and lung problems.

You can also consider setting up a quality dust collection system for a safer work environment.

Do you need both tools?

Different types of woods have different ways of burning according to their moisture, density, and other factors.

The amount of heat you’re going to need, the pressure of the tip on the surface, and how long it takes to make a burn mark on your wood will also vary.

So do a little research about the material you’re going to use before starting the work.

Before using a wood burner for a soldering job or vice versa, keep in mind the result is never going to be the same. What you can do is plan your work accordingly to get the best possible outcome.

I'm Joost Nusselder, the founder of Tools Doctor, content marketer, and dad. I love trying out new equipment, and together with my team I've been creating in-depth blog articles since 2016 to help loyal readers with tools & crafting tips.